Quick Navigation

Company Profile

Shandong Longze Machinery Co., Ltd. is a scientific research, production, sales service in one of the enterprises. Located in the famous dinosaur town - Zhucheng, the company over the years committed to the development trend of the food industry, the traditional hand-workshop processing reform for the automation, standardization of production. Through automation design and manufacturing for enterprises to save manpower, improve production rate, reduce production costs. Service customers include baking fillings fried industry, meat products cooked food processing industry, condiment industry, candy industry, vegetable corn processing industry, hotel supplies and fast food and other food processing industry, providing heating and cooking frying, vacuum concentration, sterilization Disinfection and other series of equipment.

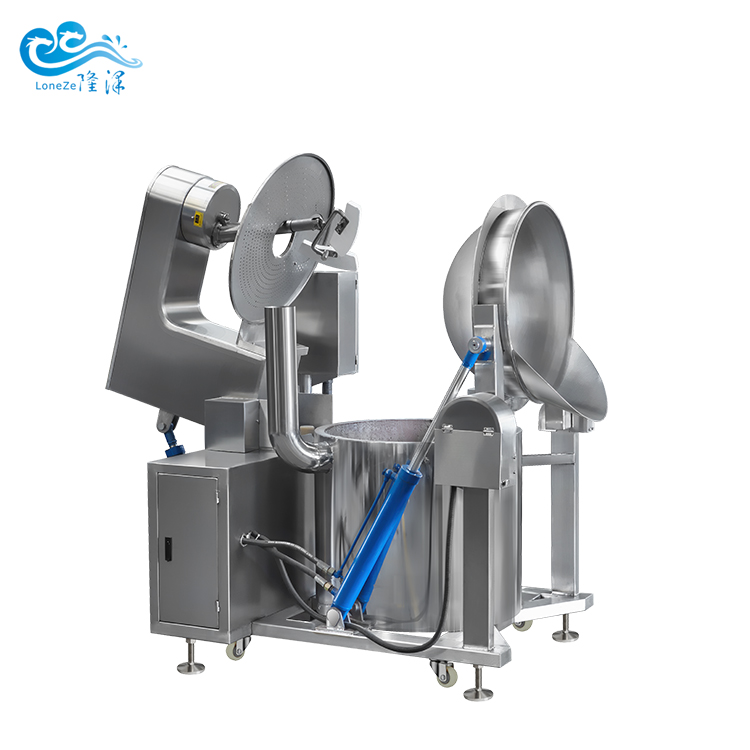

Fillings Horizontal cooking mixer

2020-12-10 16:24Contact Number:+8617560687501

Introduction of horizontal bean paste/fillings mixer machine: Longze horizontal shaft mixing pot is suitable for pre-cooking, preparation and deep shrinking of high-viscosity materials; the surface of the grooved pot body of this machine is vacuumed, and the jacket heating (steam) worm gear reducer Shaft mixing, mixer Teflon paddle.

The equipment is easy to operate and is widely used in the stirring and heating of various materials (such as bean paste, jam, cream, soups) and the concentration of biological products. This bean paste cooking mixer machine mixes the ground soybean powder with the mature bean paste filling, also known as bean paste mixer, and plays the role of heating and stirring. Can be used in bean paste processing plants, bean paste products, moon cake factories, bean paste food factories, etc. The bean paste mixer is divided into electric heating, electromagnetic heating, steam heating and other heating methods.

TO CHEATE EXCELLENT BOUTIQUE

English

English Español

Español Português

Português Français

Français Italiano

Italiano Deutsch

Deutsch Русский

Русский العربية

العربية हिन्दी

हिन्दी Indonesia

Indonesia ไทย

ไทย Ελληνικά

Ελληνικά Nederlands

Nederlands Türkçe

Türkçe 中文 (简体)

中文 (简体) 日本語

日本語 한국어

한국어