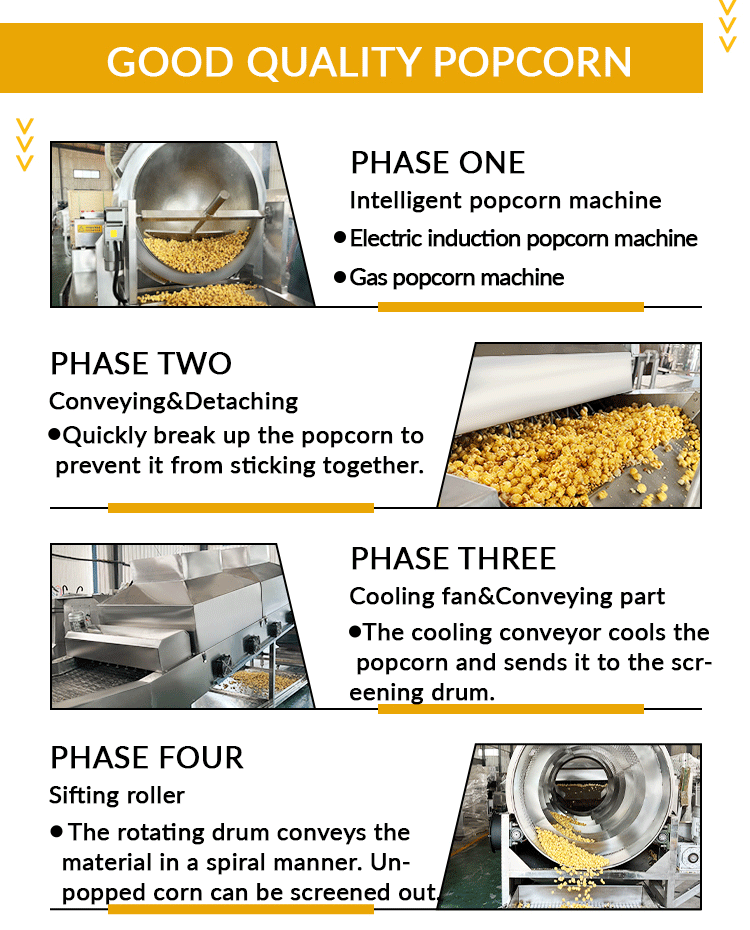

Industrial Popcorn Production Processing Line

The mushroom butterfly popcorn production line can match the length of the machine and the production line according to the customer's output. The popcorn from the single machine is poured onto the conveyor belt for detaching, cooling, conveying, sifting and direct packaging of popcorn! It greatly improves efficiency and increases output to meet the requirements of customers with large orders and large demand.

Advantages of Industrial Popcorn Machine

1. Simple operation, fully intelligent and fully automatic one-button operation. There is no blind spot for stirring in the pot, which is energy-saving, and there is no exhaust gas or noise pollution. It heats up quickly, achieves the target temperature in a short time, uses induction heating, has no fire hazard, and has more stable quality.

2. Intelligent PLC programming, one-button production and discharging, one person can operate two machines.

The popcorn production line includes a conveying device, a scattering device, a fan cooling and a drum screening device. During the operation of the popcorn machine, the operator does not need to pour the material or turn the pot. All human activities are done by the Longze intelligent popcorn machine, which greatly reduces the labor intensity and labor density of the personnel. After the popcorn machine is popped, it is poured out of the pot on the conveyor table. The conveyor table transmits and scatters the popcorn, enters the fan cooling popcorn, and is sent to the screening device to screen out popcorn of the same size for subsequent packaging, which greatly reduces the labor cost.

Features of Industrial Popcorn Production Line

1. Save manpower and transform traditional manual workshop processing into automated and standardized production.

2. High equipment utilization rate. After a set of equipment enters the production line, the output is several times higher than that of a single machine.

3. High product quality. During the production process, the equipment has unified temperature and time equipment, and the feeding and discharging are completed at one time.

4. Stable production capacity. When a single machine fails, the material transmission can bypass the faulty machine, which does not affect the output of the entire production line.