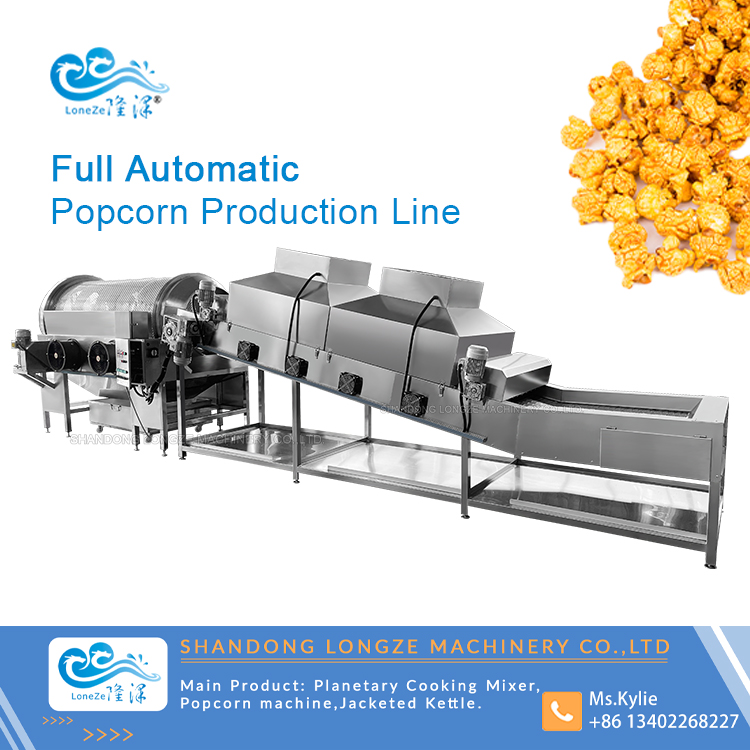

Popcorn Production Line

Industrial fully automatic popcorn production line popcorn making machine

一.Main components and work flow:

1. Raw material handling system:

Including storage bins, elevators and metering devices. The storage bin is used to store corn kernels and other raw materials for popcorn, such as sugar, oil, etc. The elevator transports the raw materials to the metering device to ensure that the amount of raw materials input each time is accurate.

2. Heating system:

Usually electromagnetic heating or gas heating is used. The heating equipment can quickly heat up to the appropriate temperature required for popcorn, so that the corn kernels can pop in a short time. Accurate temperature control ensures that the taste and quality of popcorn are consistent. Longze popcorn machine can complete the sugar coating and other seasoning steps in the pot, without the need for other sugar coating equipment.

3. Breaking device:

Popcorn after being out of the pot tends to pile up. After adding the breaking device, the popcorn that sticks together can be quickly broken up.

4. Cooling system:

Seasoned popcorn needs to be cooled quickly to maintain its taste and shape. The cooling system usually uses air cooling to quickly reduce the temperature of the popcorn.

5. Screening device:

Using the screening drum, unpopped corn kernels and incompletely popped popcorn can be screened out to ensure the quality of the popcorn.

二. Product features

1. Efficient automation: The fully automated production process greatly reduces manual operation, improves production efficiency, and reduces labor costs.

2. Precise control: Precise temperature control and metering devices ensure the stability of product quality, and the taste and quality of each batch of popcorn can be consistent.

3. Diversified flavors: Various flavors of popcorn can be produced according to market demand to meet the diverse needs of consumers.

4. Safe and reliable: The production line is equipped with complete safety protection devices, such as overheating protection, overload protection, etc., to ensure safe and reliable operation of the equipment.

5. Energy saving and environmental protection: The use of advanced heating technology and energy-saving design reduces energy consumption and reduces the impact on the environment.