Horizontal Cooking Mixer Machine

Industrial Automatic Horizontal Vacuum Bean Paste Filling Cooking Mixer Machine

Horizontal axis vacuum mixer is an advanced food processing equipment specially used for making delicate fillings such as red bean paste. It combines horizontal axis mixing technology with vacuum function, and can efficiently process raw materials such as red beans into red bean paste with uniform texture and delicate taste.

1. Main structure and components

Mixing barrel:

Usually made of high-quality stainless steel, it has good corrosion resistance and hygiene. The barrel body is reasonably designed to facilitate the input of raw materials and the removal of red bean paste.The capacity of the mixing barrel can be selected according to production needs, ranging from small tens of liters to large hundreds of liters.

Horizontal axis agitator:

The mixing shaft is made of high-strength alloy steel and can withstand greater stirring force. The horizontal axis design makes the mixing more uniform and effectively avoids the accumulation and dead corners of the filling.

The shape and angle of the mixing paddle are carefully designed to fully stir the red bean paste and make it delicate. The paddle can usually be replaced or adjusted according to different mixing needs.

Vacuum system:

It consists of a vacuum pump, a vacuum pipe and a sealing device. The vacuum pump can quickly extract the air in the mixing barrel and create a vacuum environment.

Stirring the bean paste filling under a vacuum state can effectively expel the air in the filling, prevent oxidation, and extend the shelf life of the bean paste filling. At the same time, vacuum stirring can also make the bean paste filling more compact and taste better.

Control system:

1. Equipped with an advanced control system, it can achieve precise control of parameters such as stirring speed, time, and vacuum degree. The operation interface is simple and easy to understand, which is convenient for operators to set and adjust.

2. The control system also has safety protection functions, such as overcurrent protection and overheating protection, to ensure the safe operation of the equipment.

2. Working principle

After cleaning, cooking and other pre-treatment of raw materials such as red beans, put them into the mixing barrel.

Start the horizontal axis stirrer, and the stirring shaft drives the paddle to rotate to stir the raw materials. At the same time, add appropriate amounts of sugar, oil and other auxiliary materials as needed.

When the stirring reaches a certain extent, start the vacuum system, and the vacuum pump begins to extract the air in the mixing barrel to form a vacuum state in the barrel.

In a vacuum environment, continue to stir the bean paste filling to make the filling more delicate, expel air, and improve the quality of the bean paste filling.

After the stirring is completed, turn off the vacuum system and the stirrer, open the discharge port, and take out the bean paste filling for subsequent packaging and other processes.

3. Product Features and Advantages

Efficient stirring: The horizontal axis stirring technology can quickly and evenly stir the bean paste filling to improve production efficiency. The design of the stirring paddle allows the filling to continuously roll and mix during the stirring process to ensure a delicate texture.

Vacuum preservation: Vacuum stirring can effectively expel air from the bean paste filling, prevent oxidation, and extend the shelf life. At the same time, the vacuum environment can also inhibit the growth of bacteria and ensure the hygiene and safety of the bean paste filling.

Stable quality: The precise control system can ensure that the parameters of each stirring are consistent, thereby ensuring the stability of the quality of the bean paste filling. Whether it is taste, color or texture, it can meet higher standards.

Easy to operate: The operating interface of the equipment is simple and easy to understand, and the operator only needs to undergo simple training to get started. At the same time, the maintenance of the equipment is also relatively convenient, reducing the cost of use.

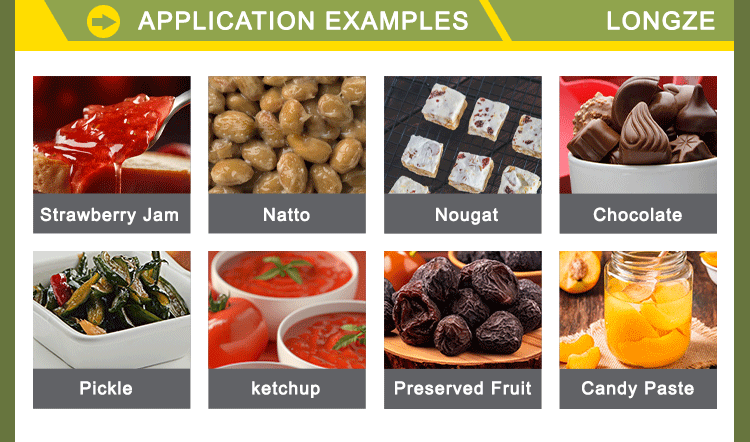

Versatility: In addition to making red bean paste, the horizontal axis vacuum mixer can also be used to make other delicate fillings, such as jujube paste, lotus paste, etc., with high versatility.

4. Application Field

The horizontal axis vacuum mixer is widely used in food processing enterprises, pastry factories, bakeries and other places. It can provide high-quality red bean paste and other fillings for various pastries, moon cakes, buns and other foods to meet the market demand for high-quality food.