Coated Peanuts Machine

Automatic Nut Frying Processing Sugar Coated Production Line

一. Main components

1. Frying equipment

Material and structure: Made of high-quality stainless steel, it has good corrosion resistance and thermal conductivity. The fryer is usually rectangular or round, with a heating device and temperature control system inside, which can accurately control the oil temperature.

Working principle: By heating the cooking oil, the nuts are put into the oil for frying. During the frying process, the control of temperature and time is crucial to ensure that the nuts are fried evenly and crispy, while avoiding over-frying to cause nutritional loss and the production of harmful substances.

2. Oil Filter Machine

After frying the nuts, dump them onto the oil filter machine.The nuts continue to be coated with flavors, and the oil is filtered to get rid of residue before being pumped back into the pot for next batch. lt can not only separate nuts and oil, but also recycle the oil.

3.Seasoning Coated Machine

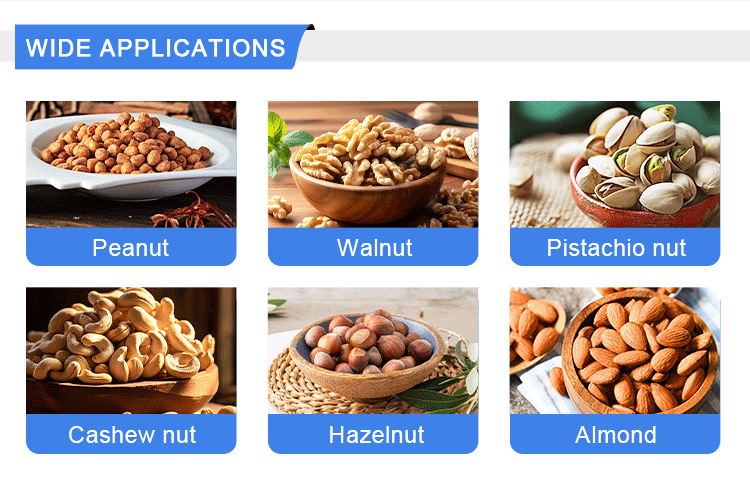

The stainless steel seasoning coated Machine can be used for mixing various peanuts, cashews, pistachios,melon seeds and other food condiments. It has a wide range of uses, is easy to operate, and is cheap, and is deeply favored by small food processing factories.

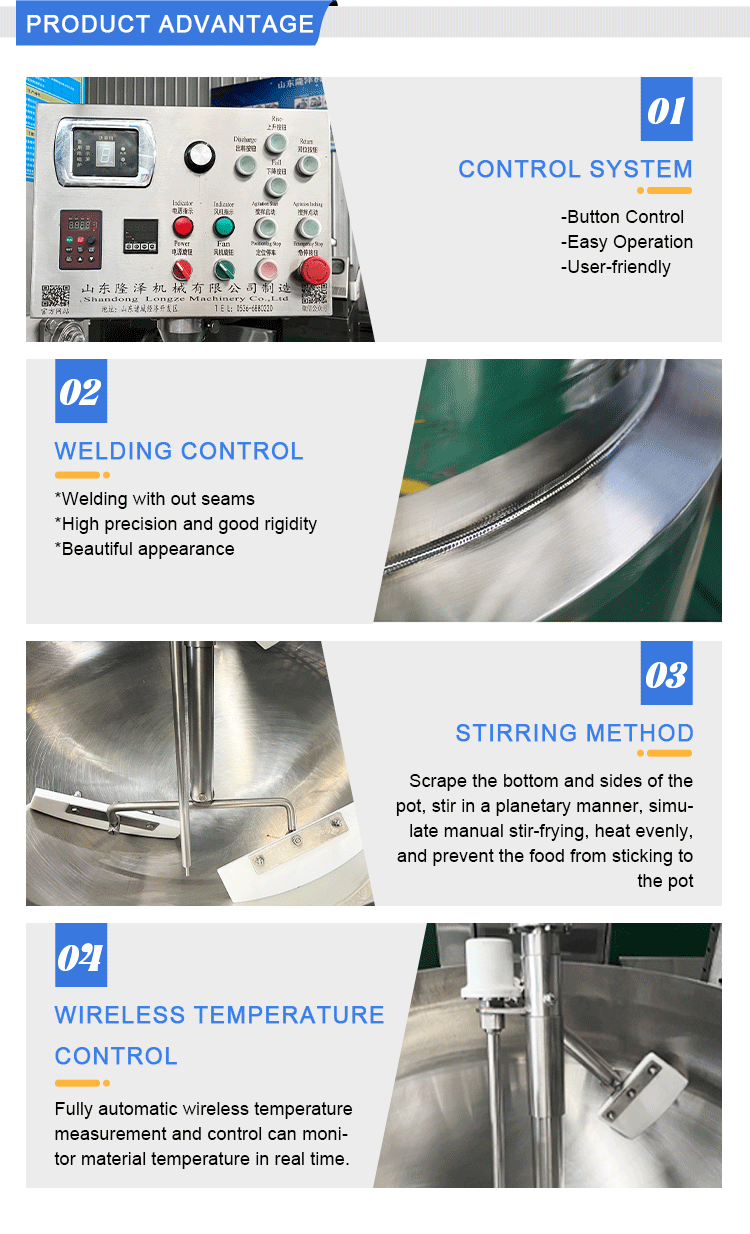

二,.automatic control system

Temperature control: The production line is equipped with precise temperature sensors and control systems, which can monitor and control the temperature of frying, sugar coating and other links in real time. Ensure that the temperature of each link is within the set range to ensure the stability of product quality.

Time control: Through timers and automated programs, the time of nuts in frying, seasoning and sugar coating is accurately controlled. Ensure that the operation time of each link is just right to improve production efficiency and product quality.

PLC control system: Equipped with an intuitive human-machine interface and PLC system, operators can easily set production parameters, monitor the production process and perform fault diagnosis. The operation of the human-machine interface is simple and easy to understand, which improves the operational convenience and production efficiency of the production line.

三. Functional characteristics

Efficient production: The fully automatic production line can achieve continuous and efficient production, greatly improving production efficiency. Compared with traditional manual operation or semi-automatic production methods, the fully automatic production line can produce a large number of high-quality products in a short time.

Stable quality: Through precise temperature, time and transmission control, the stability of product quality is ensured. The operation of each link is strictly carried out in accordance with the preset parameters, avoiding the influence of human factors on product quality.

Save manpower: The fully automatic production line only requires a small number of operators for monitoring and maintenance, which greatly saves labor costs. At the same time, it reduces the errors and labor intensity caused by manual operation, and improves the safety and reliability of production.

Strong flexibility: The production line can be adjusted and optimized according to different product requirements. By changing molds, adjusting parameters, etc., nut products with different flavors and specifications can be produced to meet the diverse needs of the market.

四. Application fields

Food processing plants: widely used in various nut food processing plants, such as frying, processing and sugar coating production of nuts such as almonds, cashews, peanuts, etc.

Snack food companies: provide high-quality nut products for snack food companies to meet consumers' demand for delicious and healthy snack foods.

Supermarkets and convenience stores: the nut products produced can be directly supplied to supermarkets, convenience stores and other sales channels, providing consumers with convenient and fast shopping options.

In short, the fully automatic nut frying, processing and sugar coating production line has the characteristics of high efficiency, stability, labor saving and strong flexibility, providing an advanced production solution for the nut food processing industry.