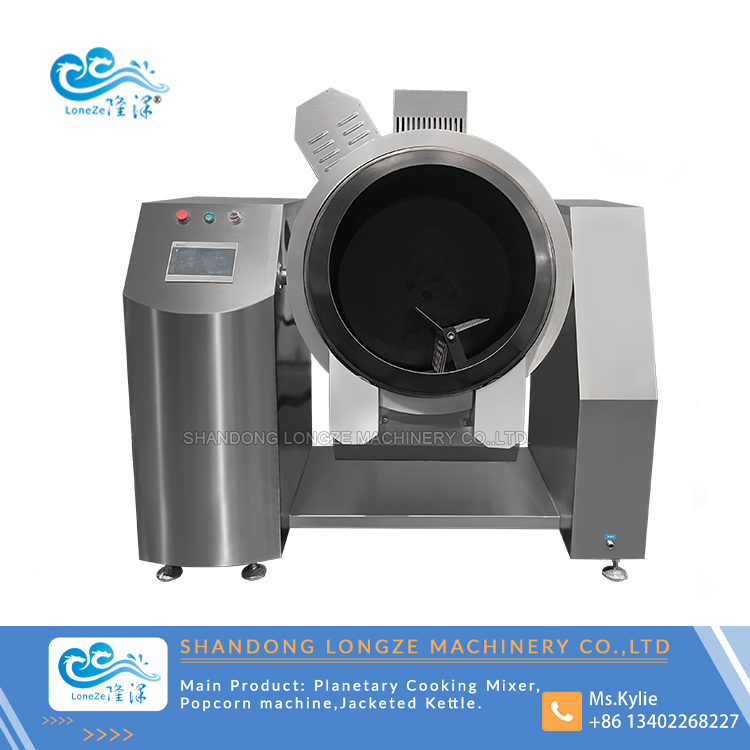

cooking robot machine

Industrial Commercial Use Multi-function Automatic Drum Stir Fry Machine

一. Working principle:

1. It adopts an advanced horizontal drum structure. The drum rotates continuously during operation, so that the ingredients in the pot can be stir-fried up and down, left and right, front and back, and in multiple directions. This stir-frying method simulates the action of flipping the spoon when cooking manually, so that the ingredients are heated more evenly and avoid local overheating or undercooking.

2. The drum is provided with heat source through electromagnetic heating or gas heating, and the temperature control is precise, which can be adjusted according to the cooking needs of different dishes.

二. Structural features:

1. Pot material: The inner surface of the pot is usually 304 all-stainless steel, which has good corrosion resistance and thermal conductivity, and meets food hygiene standards. It can also be customized with Teflon non-stick coating (food grade, in line with FDA certification standards). This coating is non-stick, convenient for frying and taking out of the pot, and easy to clean.

2. Mixing system: Different internal structures are set in the cylinder according to different ingredients and cooking requirements, such as the shape and distribution of the mixing blades, so that the materials are fried more evenly and the taste and quality of the dishes are guaranteed.

3. Discharging method: Generally, the automatic discharging design is adopted, and the cylinder is mostly shaft-turning type. The motor or hydraulic system is controlled by the controller, and the fried dishes can be poured out conveniently, quickly and cleanly.

4. Control system: Equipped with an intelligent control system, users can operate through touch screens or buttons, set parameters such as cooking time, temperature, stir-frying speed, and select preset recipe programs, which is convenient and fast.

三. Functional advantages:

1. Efficient cooking: It has strong heating power and efficient stir-frying ability, and can quickly complete the frying of dishes. It takes an average of 3-5 minutes to complete the cooking of a dish, which greatly improves the efficiency of the kitchen's dish delivery, especially suitable for catering places with large passenger flow during peak dining hours.

2. Stable taste: Cooking is carried out strictly in accordance with the set procedures and parameters, which is not affected by the chef's personal skills and emotions. It can ensure the stability and consistency of the taste and quality of each dish, which is conducive to the standardized production of dishes by catering companies.

3. Save manpower: With a high degree of automation, one person can operate multiple machines at the same time, reducing the demand for the number of chefs and reducing labor costs. Moreover, the operator does not need to have superb cooking skills, just follow the prompts to perform simple operations.

4. Energy saving and environmental protection: High heating efficiency and high energy utilization rate, which can save energy compared with traditional stove cooking methods. At the same time, the closed cooking environment reduces heat loss and oil fume emissions, and improves the working environment of the kitchen.

5. Versatility: In addition to cooking, it can also be used for fried rice, fried noodles, fried noodles, fried chicken, fried seafood, fried pan, fried nuts, fried herbs, etc., with a wide range of applications.

四. Application scenarios:

1. Catering companies: widely used in chain restaurants, fast food restaurants, Chinese restaurants, hot pot restaurants, Western restaurants and other types of catering places. It can meet the cooking needs of different cuisines and different dishes, and provide customers with fast and delicious dishes.

2. Central kitchen: Central kitchens need to produce and distribute dishes in large quantities. Automatic drum cooking machines can achieve efficient and standardized cooking, ensure the quality and taste of dishes, and facilitate large-scale production and distribution.

3. Unit canteens: Including school canteens, corporate canteens, government canteens, etc., which can meet the dining needs of a large number of people and improve the canteen's meal supply efficiency and service quality.

4. Food processing plants: It can be used on the production line of food processing enterprises to fry, dry, sterilize and other processing of various ingredients to improve production efficiency and product quality.