Jacketed Kettle

Large Capacity Industrial Steam Gas Electric Thermal Oil Heating Jacketed Kettle with Mixer

一. Product structure composition

1. Pot body: usually made of stainless steel, with good corrosion resistance and thermal conductivity. The pot body is divided into an inner pot and an outer pot. The inner pot is used to hold the material, and a sandwich is formed between the outer pot and the inner pot to hold the heat medium.

2. Sandwich: The sandwich is the key part of the sandwich pot and is used to transfer heat. The design of the sandwich should ensure that the heat medium can be evenly distributed around the pot body to improve the heating efficiency.

3. Agitator: The agitator is generally composed of a motor, a reducer, a stirring shaft and a stirring paddle. The motor drives the stirring shaft to rotate through the reducer, and the stirring paddle stirs the materials in the pot to make the materials heated evenly.

4. Heating system: According to different needs, the heating system can be heated by steam, thermal oil, hot water or electromagnetic heating. The heating system includes heating sources (such as steam boilers, thermal oil furnaces, hot water boilers or electromagnetic heaters, etc.), pipes, valves and other components.

5. Control system: The PLC can only control the system to control the temperature, stirring speed and other parameters of the sandwich pot. The control system is usually composed of temperature sensors, controllers, frequency converters, etc., which can record the process and realize standardized production and automatic control.

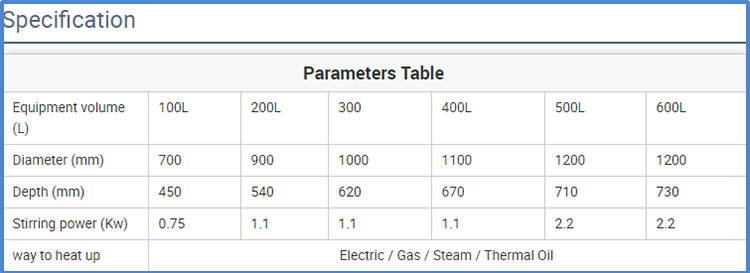

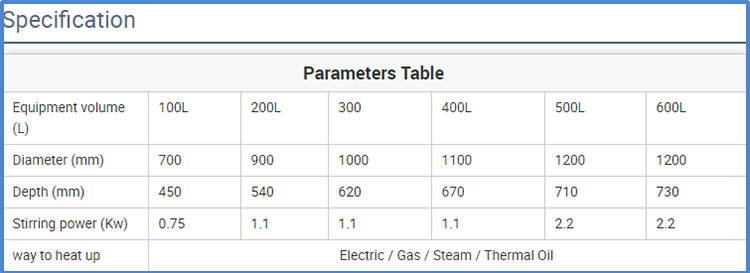

二. Performance parameters

1. Heating method:

Steam heating: Using steam as a heat medium, steam is introduced into the sandwich through a pipe to heat the materials in the pot. Steam heating has the advantages of fast heating, uniform temperature and high thermal efficiency, but it needs to be equipped with steam boilers and other equipment.

Thermal oil heating: Using thermal oil as a heat medium, the thermal oil is heated to a certain temperature through a thermal oil furnace, and then circulated into the sandwich for heating. Thermal oil heating has a wide temperature range, can achieve high temperature heating, and has high temperature control accuracy, but the thermal oil needs to be replaced regularly.

Gas heating: Use gas as fuel to heat the interlayer through the burner to generate flames. Gas heating has relatively low cost and fast heating speed, but temperature control is relatively difficult and requires supporting facilities such as gas supply pipelines.

Electromagnetic heating: Through the principle of electromagnetic induction, the pot body itself is heated to heat the material in the pot. Electromagnetic heating has the advantages of fast heating speed, high efficiency, energy saving and environmental protection, and precise temperature control, which can realize intelligent control. However, the cost of electromagnetic heating equipment is relatively high.

2. Power size:

The power size depends on factors such as the capacity of the interlayer pot, the heating method and the power of the agitator. Generally speaking, large-capacity interlayer pots have higher power, steam heating and thermal oil heating have relatively higher power, and hot water heating and electromagnetic heating have relatively lower power. The specific power size can be selected according to actual needs.

3. Stirring method and effect:

The stirring method mainly adopts bridge-type stirring, which enables the stirrer to fully stir the materials in the sandwich pot, and the stirring range covers the entire pot body, avoiding the situation of uneven stirring of the materials. Especially for high-viscosity and easy-to-precipitate materials, bridge-type stirring can effectively stir the materials evenly and improve the quality of the product.

The stirring effect depends on the design and power of the stirrer. Good stirring effect can make the materials heated evenly, improve product quality and processing efficiency. The stirring speed can be adjusted according to different materials and process requirements.

三. Equipment quality

1. Material:

The pot body is made of high-quality stainless steel, such as 304 or 316 stainless steel, which has good corrosion resistance, high temperature resistance and hygienic properties. Ensure that the pot body will not rust, deform or affect the quality of food during long-term use.

The stirring shaft and stirring paddle of the stirrer should also be made of stainless steel or other corrosion-resistant materials to ensure that they will not cause pollution when in contact with the material.

2. Manufacturing process:

The manufacturing process of the sandwich pot should be exquisite, the welding should be firm, and there should be no leakage. The welds should be strictly inspected and processed to ensure that their quality meets relevant standards.

The installation of the agitator should be firm and reliable, and the sealing performance of the agitator shaft should be good to prevent material leakage and contamination.

3. Safety performance:

The equipment should be equipped with complete safety protection devices, such as temperature sensors, pressure sensors, safety valves, etc., to ensure that there will be no dangerous situations such as over-temperature and over-pressure during use.

The motor and reducer should have overload protection function to prevent damage to the equipment due to overload.

4. Durability:

Large-capacity industrial sandwich pots with agitators should have high durability and be able to withstand long-term high-intensity use. Key components such as motors, reducers, agitator shafts, etc. should use high-quality brand products to ensure their stable performance and long service life.

Regular maintenance and care of the equipment, such as cleaning the pot body, checking the agitator, replacing seals, etc., can extend the service life of the equipment.