Thermal Oil Cooking Mixer

Industrial Thermal Oil Heating Jam Making Cooking Kettle with Planetary Mixer

一. Main features

1. Thermal oil heating system

High efficiency and energy saving: Thermal oil has a high heat conduction efficiency and can quickly transfer heat to the cooking pot to reduce energy waste.

Uniform temperature: The thermal oil circulates in the pot, making the temperature of each part of the pot uniform, avoiding local overheating or overcooling, and ensuring the stability of the quality of the jam.

Precise temperature control: Through the advanced temperature control system, the temperature of the thermal oil can be accurately controlled, thereby achieving precise control of the temperature during the jam making process and meeting the production requirements of different jam varieties.

2. Planetary agitator

Strong stirring: The planetary agitator adopts a unique design, which can stir in all directions and without dead ends in the pot, ensuring that the various ingredients in the jam are fully mixed and improving the taste and quality of the jam.

Adjustable speed: The speed of the mixer can be adjusted according to different jam making processes to meet the mixing needs at different stages.

Durable and reliable: The mixing scraper is made of high-quality Teflon material, which has the characteristics of high strength, high temperature resistance, corrosion resistance, wear resistance, etc., and can maintain good performance during long-term use.

3. Fully automatic control

Intelligent operation: The cooking pot is equipped with an advanced PLC fully automatic control system. The user only needs to set the relevant parameters, and the equipment can automatically complete heating, mixing, temperature control and other operations, which greatly reduces labor intensity, improves production efficiency, and realizes standardized production.

Safe and reliable: The control system has multiple safety protection functions, such as overheating protection, overvoltage protection, leakage protection, etc., to ensure the safety and reliability of the equipment during operation.

4. Wide applicability

This cooking pot is not only suitable for making jam, but also for boiling, frying, stewing and other processes of other foods, such as sauces, soups, fillings, bean paste, lotus seed paste, donkey-hide gelatin, fried flour, etc., with wide applicability.

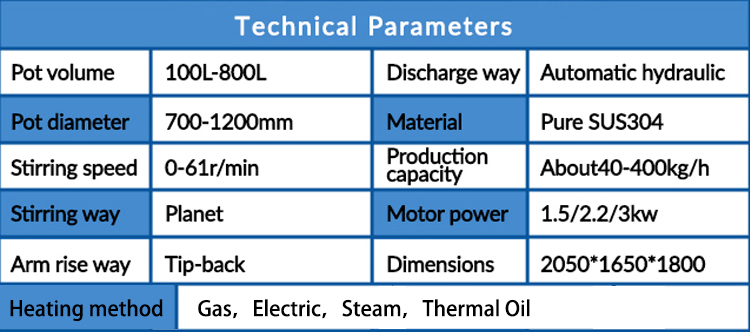

5. Equipment technical parameters

二. Usage

1. Preparation: Prepare the required raw materials, clean them and cut them into appropriate sizes. Check whether all parts of the equipment are normal and ensure that the liquid level of the heat transfer oil is within the normal range.

2. Adding materials: Add the raw materials to the cooking pot, and be careful not to exceed the maximum capacity of the pot.

3. Set parameters: Set the heating temperature, stirring speed, time and other parameters according to the requirements of jam making.

4. Start the equipment: Press the start button and the equipment starts to run automatically. During the operation, the operating status of the equipment can be observed at any time, and the parameters can be adjusted if necessary.

5. Complete the production: When the jam reaches the required concentration and state, the equipment will stop running automatically. At this time, the jam can be taken out of the pot for subsequent packaging and storage.

三. Maintenance

1. Regular cleaning: The cooking pot and agitator should be cleaned in time after use to remove residual jam and dirt. Special cleaning agents and tools can be used for cleaning, and be careful not to damage the surface of the equipment.

2. Inspection and maintenance: Regularly check the various components of the equipment, such as thermal oil pipelines, valves, agitators, etc., to ensure their normal operation. If there is damage or wear, it should be replaced in time.

3. Replacement of thermal oil: The thermal oil will gradually age after a period of use and needs to be replaced regularly. When replacing the thermal oil, the old oil should be discharged first, then the oil system should be cleaned, and then new thermal oil should be added.

4. All precautions: When using the equipment, the operating procedures should be strictly followed and safety should be paid attention to. Avoid illegal operations during the operation of the equipment to avoid accidents.

In short, the industrial thermal oil heating jam making cooking kettle with planetary mixer is an excellent performance and powerful jam making equipment. It has the advantages of high efficiency and energy saving of thermal oil heating, uniform and strong planetary stirring, and intelligent automatic control, which can provide efficient, stable and reliable production solutions for jam production enterprises.