Ball Shape Popcorn Machine

Industrial Full Automatic Caramel Popcorn Maker Machine

Longze industrial full automatic popcorn maker machine mainly evaporates the internal water of corn kernels by high-temperature frying to form pressure. When the pressure reaches a certain level, the corn kernels expand and burst rapidly to form popcorn. In the process of popcorn production, adding caramel solution can form a caramel film on the surface of popcorn, which improves the taste and appearance of popcorn. The shape of popcorn depends on the type of corn kernels. Our popcorn machine can produce popcorn of various flavors, which depends on the type of flavor powder added.

一. The main structure of industrial full automatic popcorn maker machine

1. Heating system

Longze industrial full automatic popcorn maker machine has two heating methods: gas heating popcorn machine and electromagnetic heating popcorn machine.

Gas heating method

Heater: The gas-heated heater mainly generates a high-temperature flame by burning gas to heat the air to the required temperature. This heating method heats up quickly and can reach the temperature required for popcorn production in a short time.

Control system: The control system of gas heating is mainly used to adjust the flow rate and combustion intensity of gas to control the heating temperature and heating time. Through precise control, the stability of popcorn production can be ensured, and the impact of excessively high or low temperatures on product quality can be avoided.

Electromagnetic heating method

Heater: The electromagnetic heating heater uses the principle of electromagnetic induction to generate eddy currents in the metal heating body to generate heat, thereby heating the air to the required temperature. This heating method has the advantages of uniform heating and high temperature control accuracy.

Control system: The control system of electromagnetic heating mainly controls the heating temperature and heating time by adjusting the intensity and frequency of electromagnetic induction. This control method is more accurate and can achieve precise control of temperature to ensure the stability of product quality.

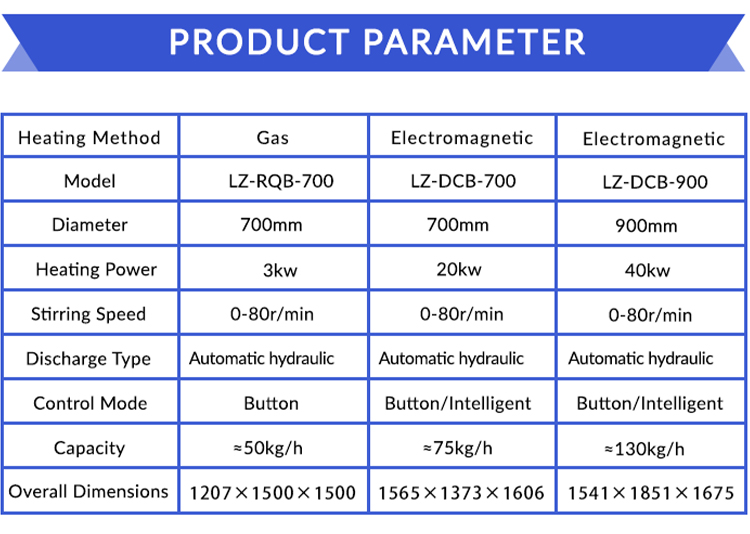

二. Technical parameters of industrial popcorn machine

三. Performance characteristics of industrial caramel popcorn machine

1. High efficiency: The industrial caramel popcorn machine adopts advanced heating system and control system, which can realize automatic out of the pot, customized automatic oil and sugar syrup and other functions, and realize efficient and continuous production.

2. Stability: The equipment has a complete control system, which can accurately control the temperature, heating time and raw material delivery speed in the production process. It is equipped with a PLC system, which can set parameters, record processes, and realize standardized production.

Ensure stable product quality.

3. Reliability: The high-quality precision parts used in the equipment are all produced by our own manufacturing workshop, which ensures the stability and durability of the equipment during long-term operation.

4. Easy to operate and maintain: The equipment interface is simple and easy to operate. It also has fault self-diagnosis function and remote control function, which is convenient for timely discovery and solution of problems.

With the continuous growth of people's demand for snack foods, the application prospects of industrial full automatic popcorn maker machines in the food industry are broad. In order to meet the market demand for high-quality popcorn, we, Longze Machinery, will continue to update technology, improve the performance of industrial full automatic popcorn maker machines, and make greater contributions to the development of the food industry.

Contact Us:

Shandong Longze Machinery Co.,Ltd

Company website:https://www.zclongze.com/

WhatsApp/Wechat/Tel:+86 13402268227

E-mail:cathy@loneze.com

Address:No. 215, Zhanqian Street, Zhucheng City, Weifang City, Shandong Province, China

Contact:Ms. Kylie

If you have any question, please feel free to contact me, I will give you the lowest discount.