Industry knowledge

How to Maintain Color & Nutrition in Jam Making: The Complete Guide to Vacuum Horizontal Mixers

1. How to Maintain Color & Nutrition in Jam Making: The Complete Guide to Vacuum Horizontal Mixers For commercial jam producers, achieving vibrant color and rich nutrition in products like strawberry, pineapple, and blueberry jam isn’t just a goal—it’s a market necessity. Yet, traditional mixing often leads to oxidation, nutrient loss, and inconsistent texture. This is where vacuum horizontal mixing technology transforms outcomes. 2. Why Oxidation Ruins Jam Quality & How Vacuum Mixing Solves It When fruit pulp is exposed to air during mixing, enzymatic browning occurs, dulling the natural reds of strawberries and purples of blueberries. Vacuum horizontal mixers remove air from the mixing chamber, creating an oxygen-free environment that: * Preserves carotenoids and anthocyanins (natural pigments) * Locks in vitamin C and heat-sensitive nutrients * Prevents flavor degradation caused by airborne contaminants

2. Why Oxidation Ruins Jam Quality & How Vacuum Mixing Solves It When fruit pulp is exposed to air during mixing, enzymatic browning occurs, dulling the natural reds of strawberries and purples of blueberries. Vacuum horizontal mixers remove air from the mixing chamber, creating an oxygen-free environment that: * Preserves carotenoids and anthocyanins (natural pigments) * Locks in vitamin C and heat-sensitive nutrients * Prevents flavor degradation caused by airborne contaminants  3. 360° Mixing: The Key to Uniform Texture Without Damage Unlike vertical agitators that leave dead zones, horizontal mixers with bidirectional blades ensure every particle—whether chunk, granule, or paste—is uniformly blended. Our design features: * Alternating forward/reverse rotation for 360° material movement * Gentle handling that maintains fruit integrity * No cross-contamination between batches

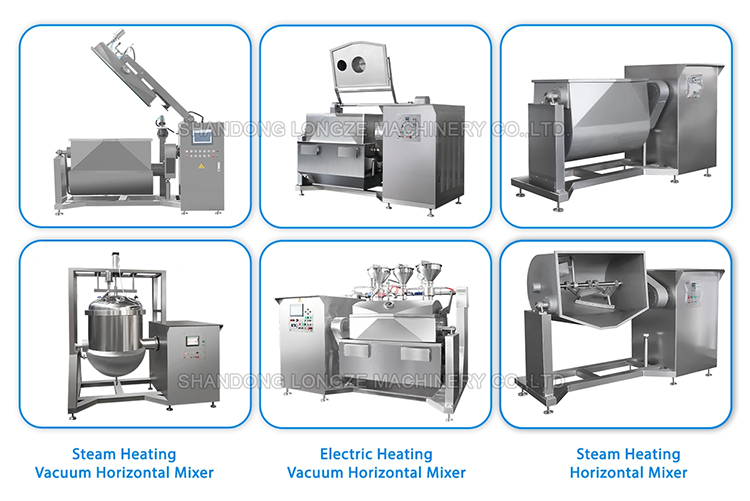

3. 360° Mixing: The Key to Uniform Texture Without Damage Unlike vertical agitators that leave dead zones, horizontal mixers with bidirectional blades ensure every particle—whether chunk, granule, or paste—is uniformly blended. Our design features: * Alternating forward/reverse rotation for 360° material movement * Gentle handling that maintains fruit integrity * No cross-contamination between batches  4. Heating Options: Steam & Induction for Different Jam Types * Steam Heating Mixers Ideal for high-viscosity jams (e.g., pineapple with fibers). Provides gradual, even heat distribution through jacket heating, preventing caramelization on surfaces. * Induction Heating Mixers Perfect for temperature-sensitive fruits like blueberries. Offers precise digital control (±1°C), rapid heating, and 30% higher energy efficiency than traditional methods. * Capacity Planning: Choosing Between 300L, 500L, and 800L Models 300L: Perfect for R&D, small-batch artisan production 500L: Most popular for mid-scale factories (1-2 ton/day output) 800L: Designed for continuous industrial lines with automated feeding systems

4. Heating Options: Steam & Induction for Different Jam Types * Steam Heating Mixers Ideal for high-viscosity jams (e.g., pineapple with fibers). Provides gradual, even heat distribution through jacket heating, preventing caramelization on surfaces. * Induction Heating Mixers Perfect for temperature-sensitive fruits like blueberries. Offers precise digital control (±1°C), rapid heating, and 30% higher energy efficiency than traditional methods. * Capacity Planning: Choosing Between 300L, 500L, and 800L Models 300L: Perfect for R&D, small-batch artisan production 500L: Most popular for mid-scale factories (1-2 ton/day output) 800L: Designed for continuous industrial lines with automated feeding systems