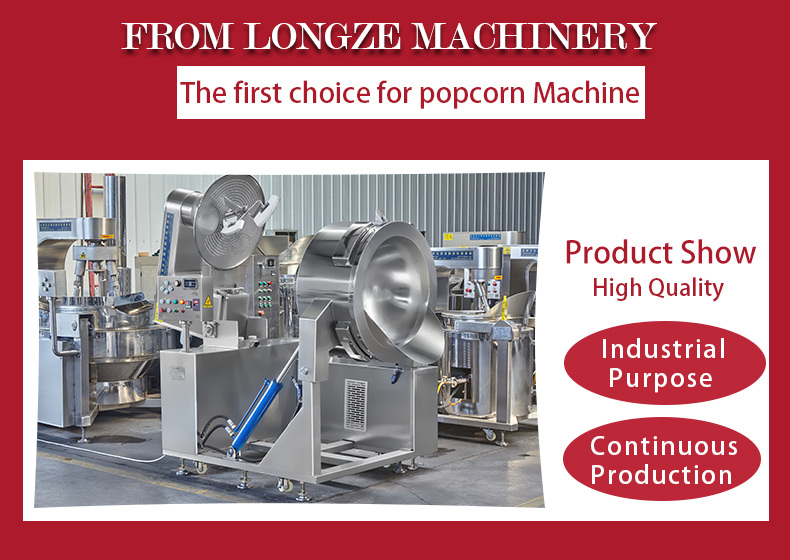

Ball Shape Popcorn Machine

Automatic Caramel Popcorn Making Machine Popcorn Production Line

Automatic popcorn machine is the latest independent research and development of equipment for producing ball shape popcorn, this machine is energy-efficient, small footprint, health, high rate, no noise, the advantages of simple operation. From raw materials to processing technology of equipment, our company provides a full range of services, the device widely used for snack food factory, bakery, suitable for investment in small businesses, less investment and quick results, is the best choice for entrepreneurs.

Main features of industrial popcorn machine:

1. High productivity with 75-130 kg popcorn per hour.

2.Less gas consumption equipped with high efficiency cooking range comparing with other similar types

3.Press-button for ignition, automatic gas entry.

4.Whole process under control of the control panel, easy to operate.

5.Fully mix with planetary mixing system.

6.Variable mixing speeds can be controlled during processing of caramel popcorn.

7.Specially designed scrapers touching thoroughly inner surface of the bowl to avoid burning.

8.Mixing arm can be lifted up automatically.

9.Bowl can be tilted 90 degrees automatically to allow popcorn completely discharged.

10.Double safety valves to ensure its safe operation.

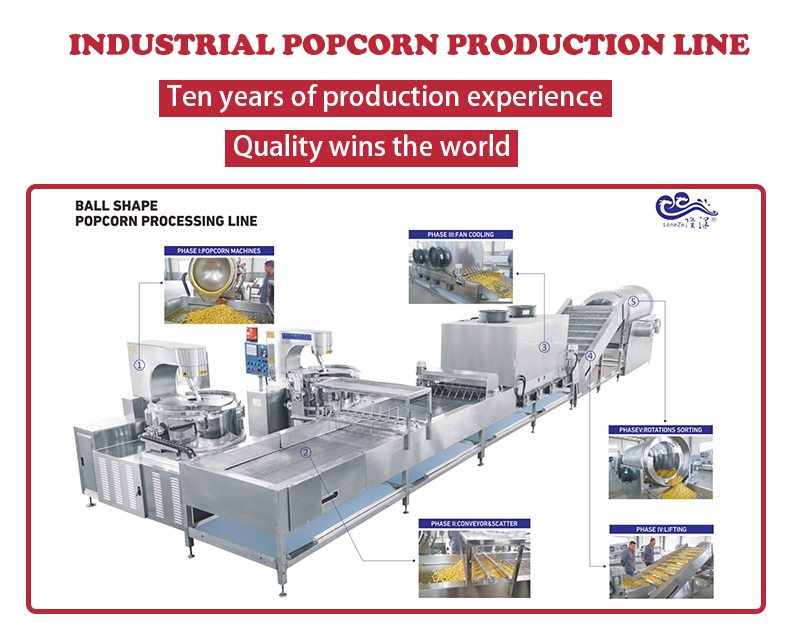

Features of Commercial Caramel Mushroom Popcorn Production Line:

1.The whole system runs automatically after turning on power.

2.Functions of popcorn production line mainly include: conveying, detaching, cooling and sifting.Making popcorn cool enough and be ready for packaging.

3.Powerful fans and side fans are equipped wherever required to make sure better cooling effect.

4.All parts are made of stainless steel SUS304 (even for base plates and bolts), world-known suitable steel for food materials, durable and easy to clean .

5.Heavy-duty casters are installed for easy transfer and movement.

6.Durable motors can work constantly 24/7.

7.Variable conveying speed and sifting speed, adjustable via control panel.

Description of Electromagnetic popcorn making machine:

1.Everything is done automatically through control panel, including automatic ignition and gas entry, mixing arm lifting, agitation on and off, popcorn discharging, etc, with waterproof press buttons.

2.Planetary mixing system ensures full mixing and avoids over burnt or deposit on the pot surface. Durable thick Teflon scrapers, anti high temperature, anti-corrosion, lasting for a long time.

3.Heavy duty casters for easy movability and stainless steel 304 base plates for stability with rusting.

4.With press button for automatic ignition, and automatic gas entry for easy operation.

5.Pressure burner can provide strong flames with less gas consumption. Full combustion shows blue color flames. Thick fireproofing materials provides good insulation of heating.

6.All components except for electric and hydraulic parts are fabricated by ourselves. Our laser machines can ensure their accuracy and compatibility with each other, thus reducing occurrence of malfunction.

7.All skillful workers are employed by passing strict exams to ensure first-class quality of all our products, which has gained for us many regular customers. See welding quality as shown above.

8.Each and every procedure is strictly inspected to ensure quality. All staff involved in manufacturing will sign on the checklist for tracking the responsible person if any quality problem.