Pressure Cooking Pot

Industrial High-Pressure Soup Cooking Kettle

Applications of Commercial Pressure Cooking Kettle

Industrial high pressure cooking kettle machine is widely used for cooking hard materials in a short time like bones, beans, meat soup, etc. Its large capacity up to 1000L aims to increase efficiency for each batch within short working time. The high pressure of steam in the pot helps continue to cook materials even the heating is turned off, which can definitely save heating energy and decrease much cooking time comparing with in normal working pressure.

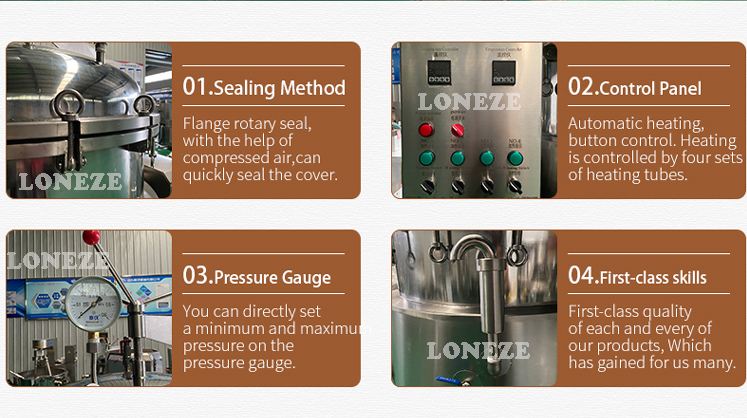

Features of Industrial High Pressure Cooking Kettle

1.Wide application for all kinds of food or snack stuff.

2. All stainless steel 304, durable and easy to clean, healthy for food materials.

3. Fully automatic with user-friendly control panel.

4.Temperature under easy monitoring and controlling.

5. Safe operation with automatic pressure release valve, thick steel reliable under pressure.

High-pressure cooking not only expedites the cooking process but also ensures that ingredients reach optimal temperatures quickly. This rapid temperature increase enhances flavor extraction and allows for precise control over the cooking conditions, resulting in soups that boast rich and well-developed flavors.

The high-pressure cooking process contributes to enhanced flavor retention by minimizing nutrient loss and maximizing the extraction of flavors from ingredients. This results in soups that not only cook faster but also boast intensified and well-preserved flavors, meeting the high standards of taste expected in the culinary industry.

The efficiency of the Industrial High-Pressure Soup Cooking Kettle translates into significant time and labor savings. Chefs can optimize their production schedules, meeting high-demand periods without compromising on the quality of the final product. This time-saving advantage is crucial for meeting the demands of busy kitchens and food manufacturing facilities.

You can click here to get our company's video website, which contains the product videos you need, so that you can understand the products more intuitively.