Electric Induction Cooking Mixer

Industrial Planetary Cooking Mixer

Applications of Industrial Planetary Cooking Mixer

1. Baking stuffing frying industry (jam, lotus paste, bean paste, fruit paste, preserved fruit, jujube paste).

2. Meat products cooked food processing industry (stewed, meat paste, beef paste, seafood paste).

3. Condiment industry (hot pot base, instant noodle sauce).

4. Vegetable corn processing industry (mushroom paste, chili paste)

5. Hotel supplies and fast food (canteen soup, cooking, stew, porridge) and other food processing industries.

6. Group meals, large restaurants or canteens, cooking porridge, stewed products, etc.

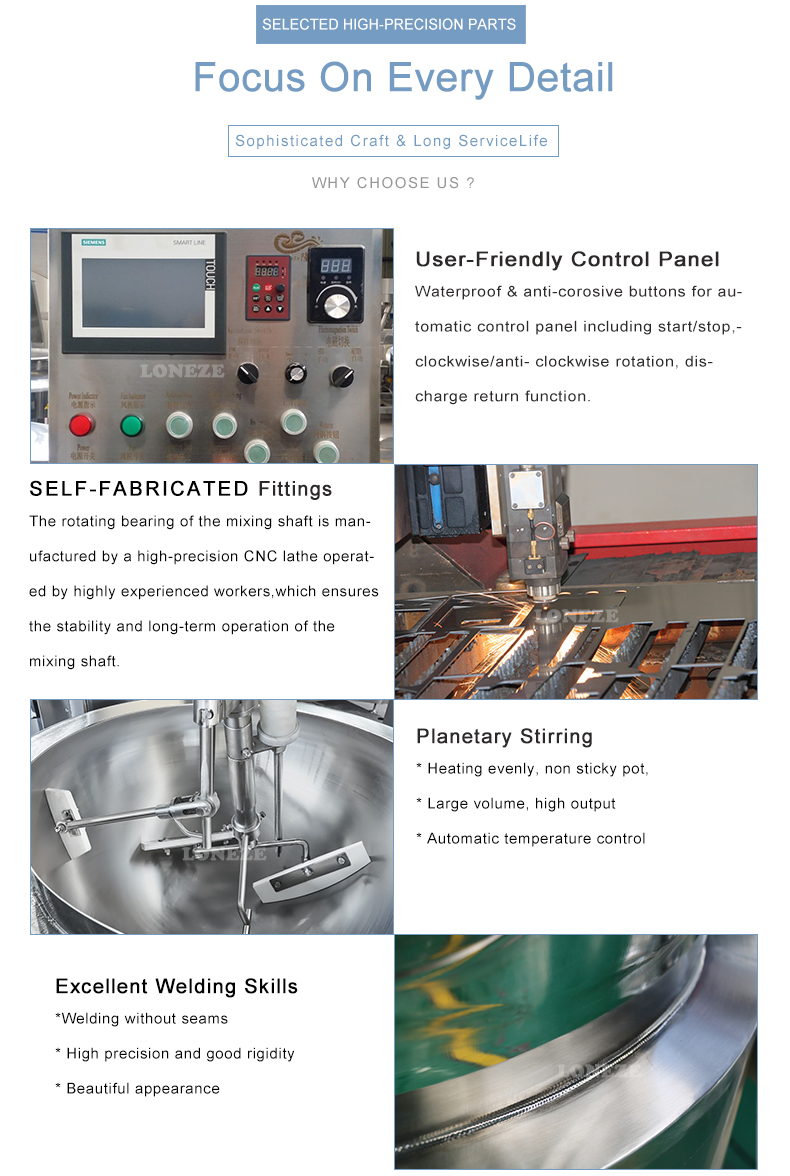

Features of Industrial Cooking Mixer Machine

1.Variable mixing speed to satisfy various processing procedures.

2.PTFE scrapers durable under high temperature, non-sticky and anti-corrosion, pressed tight to the surface of the bowl with strong spring. With side scraper to clean splashes on the higher level in the bowl.

3. Mixing head is sealed for waterproofing, and maintenance-free for over 5 years.

4. Mixing arm tilted backwards automatically before discharging.

5. Cooking bowl titled to 90° hydraulically to allow easy discharge of food materials.

6. Safe operation with automatic pressure release valve, thick steel reliable under pressure.