And can be microcomputer intelligent control, easy and simple operation so that you only need to gently press, you can stay away from the kitchen fumes hazards, easy to enjoy the delicious, to achieve the process of cooking the magic and fun.

Can also be based on the different models, for small shops, sauces processing plants and seasonings manufacturing group enterprises. The emergence of automatic chili sauce wok greatly improved production efficiency, saving manpower costs.

Chili sauce production process is divided into two polished after the deployment, sterilization, canned, finished. Chili sauce is the most critical frying, is a professional production of chili sauce equipment, materials are 304 food grade stainless steel, not only can improve the taste of chili sauce to ensure the production of chili sauce.

All kinds of sauces gas wok Longze machinery, pot body for a stamping of the hemispherical stainless steel pot body; heating method can be used steam, liquefied petroleum gas, natural gas and other forms;

Automatic chili sauce cooking mixer machine performance characteristics:

1. Design concept: through automation design and manufacturing for enterprises to save manpower, increase production and reduce production costs. Equipment is easy to operate, high efficiency, low energy consumption, long life, compact structure, easy maintenance and other characteristics, is the performance of the mixer

Chili sauce 2

2. Stirring system: The stirring method adopts special tilting rotation, so that the planets are fully in contact with the pot body to achieve the rotation and autobiographical non-integer rotation ratio, so that the pot without stirring dead ends, mixing the material more evenly, the mixer used Polytetrafluoroethylene scraper and the pot of the high degree of fit, scraping the ground more thoroughly, not easy to produce paste pot phenomenon.

3. Speed control device: the use of advanced rotation shaft and sealing structure, so that the pot clean, health; speed control with frequency control power, smooth operation.

4. pot body flip system: hydraulic lift mode, to achieve mixing and pot body after the separation of hydraulic tilt material can be tilted 90 ° angle, pouring no dead ends, easy to clean, reduce labor intensity.

Manual: the whole pot through the worm, the worm manually turn the pot out of the material, safe, stable and reliable.

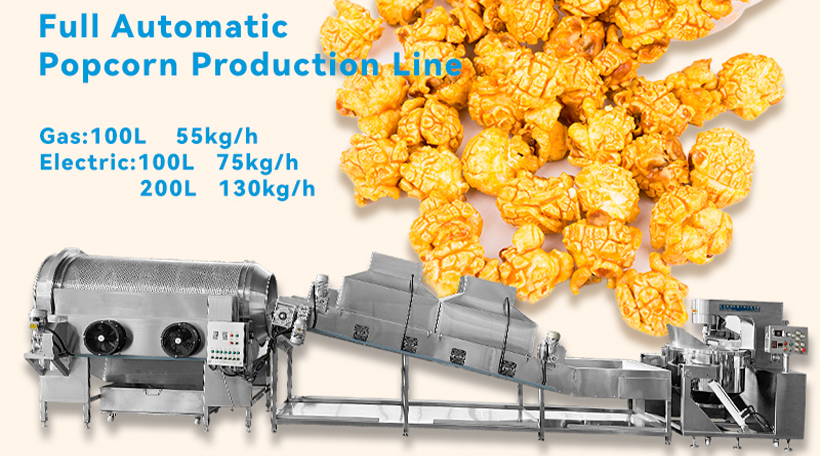

5. Model according to the actual volume can be divided into 100L, 200L, 300L,

English

English Español

Español Português

Português Français

Français Italiano

Italiano Deutsch

Deutsch Русский

Русский العربية

العربية हिन्दी

हिन्दी Indonesia

Indonesia ไทย

ไทย Ελληνικά

Ελληνικά Nederlands

Nederlands Türkçe

Türkçe 中文 (简体)

中文 (简体) 日本語

日本語 한국어

한국어