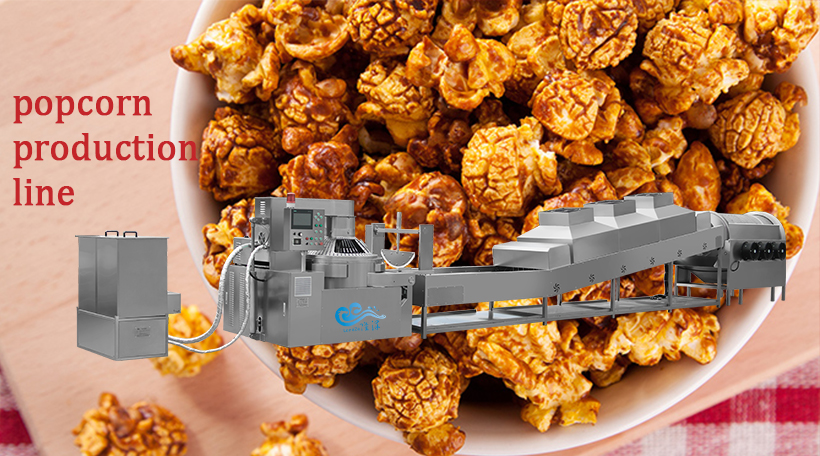

Commercial automatic popcorn machine production line

2017-09-14 08:48

Commercial automatic popcorn machine production line

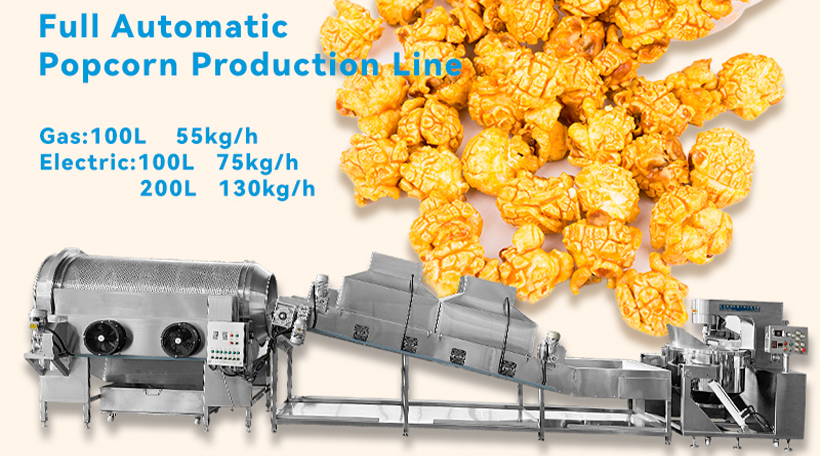

You can form a Large industrial automatic popcorn production line by at least three sets popcorn machine.

The Large industrial automatic popcorn production line can product 5 kg popcorn one time, and it takes four minutes once.

save manpower

The Large industrial automatic popcorn production line transform the traditional mode of production into automation, standardization production.saving the manpower and cost.

high output

A set of Large industrial automatic popcorn production line making the popcorn output increased several times than the single operation.

the high quality of the products

In the popcorn production processing, we can set uniform temperature time, input and output are completed once time.

stable production capacity

When single machine failure, the popcorn can transfer by skip the fault machine, do not affect the entire popcorn production processing .

●simple operation automatic,intelligent and one button, safe operation and stable performance

●uniform stirring no any stirring blind spot in the pot

●energy saving and environmental protection without waste residue and noise pollution

●rapid heating achieve the target temperature with short time

●safe use inductive heating and no danger of fire

●Digital control to monitor kettle skin temperature to avoid popcorn over processing

●Programmable audible alarm to alert operator when product reaches set-point

●Great Output: four minutes can be the 10 pounds of popcorn , high efficiency

●use hydraulic thrust to tilting pot body, make the popcorn is easy to in and out and save manpower.

●Food grade stainless steel is safety and healthy.

Quick Navigation

Company Profile

Shandong Longze Machinery Co., Ltd. is a scientific research, production, sales service in one of the enterprises. Located in the famous dinosaur town - Zhucheng, the company over the years committed to the development trend of the food industry, the traditional hand-workshop processing reform for the automation, standardization of production. Through automation design and manufacturing for enterprises to save manpower, improve production rate, reduce production costs. Service customers include baking fillings fried industry, meat products cooked food processing industry, condiment industry, candy industry, vegetable corn processing industry, hotel supplies and fast food and other food processing industry, providing heating and cooking frying, vacuum concentration, sterilization Disinfection and other series of equipment.

TO CHEATE EXCELLENT BOUTIQUE

English

English Español

Español Português

Português Français

Français Italiano

Italiano Deutsch

Deutsch Русский

Русский العربية

العربية हिन्दी

हिन्दी Indonesia

Indonesia ไทย

ไทย Ελληνικά

Ελληνικά Nederlands

Nederlands Türkçe

Türkçe 中文 (简体)

中文 (简体) 日本語

日本語 한국어

한국어