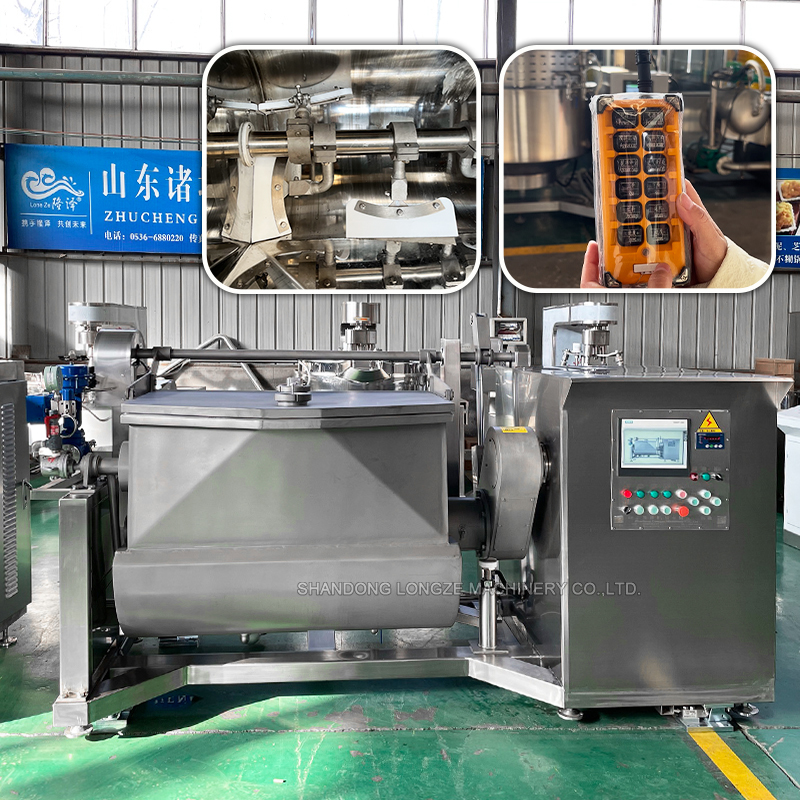

Horizontal stirring shaft design

The stirring shaft is placed horizontally in the pot. The stirring shaft rotates in the horizontal direction, which can effectively utilize the space of the stirring container. Compared with the vertical shaft mixer, the horizontal horizontal shaft mixer has more advantages in handling higher viscosity or larger block materials, realizing 360-degree rotation and stirring without dead angles, so that the materials are mixed more evenly.

Product advantages

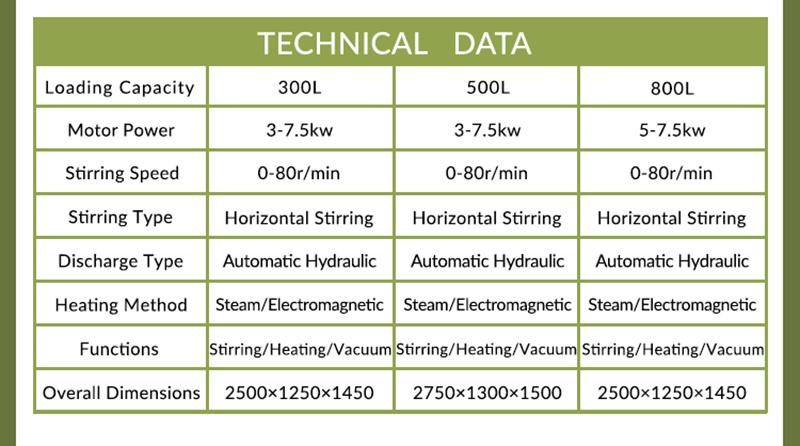

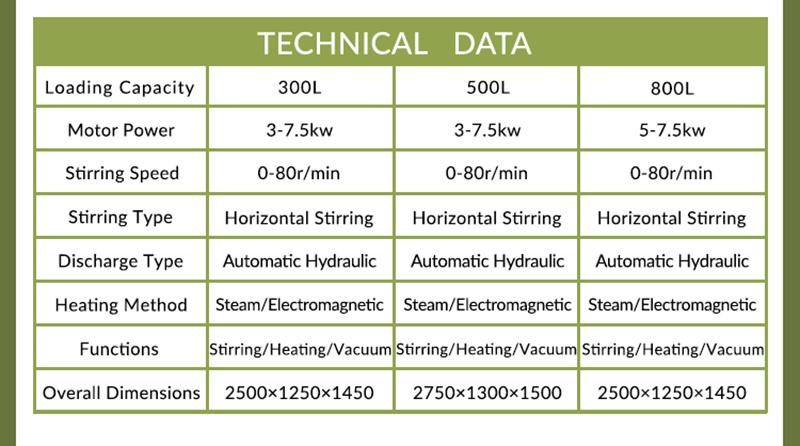

1. Our horizontal shaft mixer has two methods of steam heating and electromagnetic induction heating, which can be selected according to the material properties and process. The specifications are optional from 300L-800L, which can meet the needs of large food factories and multi-dimensional customers such as food stores and restaurants.

2. Excellent mixing effect. Whether it is solid or liquid, it can achieve highly uniform mixing. Its special stirring method can effectively prevent the stratification of materials during the stirring process.

3. Adapt to a variety of material characteristics. It has a good handling ability for high-viscosity materials. At the same time, it can easily deal with materials containing larger particles.

4. High efficiency and energy saving. It has a high stirring efficiency and can mix materials evenly in a shorter time. It can reduce the mixing time of each batch of materials, thereby improving the efficiency of the entire production process.

5. Equipped with a plc system, easy to operate and maintain.With a simple and easy-to-understand human-machine interface, the operator can easily control parameters such as mixing speed and mixing time. It is also equipped with an automatic control system, which can perform mixing operations according to the preset program, reducing the professional requirements for operators.

6. High safety. The horizontal horizontal axis mixer has a low center of gravity and is relatively stable during operation. At the same time, it is equipped with a radio remote control, so that the staff can control the machine remotely, which is safer.

Application field

1. Food industry

Used for mixing food raw materials, such as mixing flour, sugar, oil, etc. to make pastry raw materials, or mixing various seasonings to make compound seasonings. It is suitable for pre-cooking, preparation, and concentration of high-viscosity materials; the inside of the trough-type pot can be vacuumed, which is very suitable for making jams, preserves, pickles, powdered products, etc., so that the materials maintain their color. Since the food industry has extremely high requirements for hygiene, the tank and stirring paddle of the horizontal horizontal axis mixer for food are usually made of food-grade stainless steel and are easy to clean to ensure the safety and quality of food.

2. Chemical industry

It is used to mix various chemical raw materials. For example, in paint production, different components such as resins, pigments, solvents, etc. are mixed into a uniform paint. The materials in the chemical industry have various properties, some are corrosive, and some have high viscosity. The horizontal horizontal axis mixer can choose the appropriate material and stirring paddle according to the different material characteristics to meet production needs.

We have more than 13 years of experience in manufacturing food processing machinery, and we focus more on batch production. We have a more professional team in procurement, production, sales and technology, and have excellent equipment. We have fast after-sales service. If our products can match your products, please contact us.

Contact us:

Shandong Longze Machinery Co., Ltd.

Company website: https://www.zclongze.com/

WhatsApp/WeChat/Phone: +86 13402268227

Email: cathy@loneze.com

Address: No. 215, Zhanqian Street, Zhucheng City, Weifang City, Shandong Province, China

Contact: Ms. Kylie

If you have any questions, please feel free to contact me, I will give you the lowest discount.

English

English Español

Español Português

Português Français

Français Italiano

Italiano Deutsch

Deutsch Русский

Русский العربية

العربية हिन्दी

हिन्दी Indonesia

Indonesia ไทย

ไทย Ελληνικά

Ελληνικά Nederlands

Nederlands Türkçe

Türkçe 中文 (简体)

中文 (简体) 日本語

日本語 한국어

한국어