How to Maintain Color & Nutrition in Jam Making: The Complete Guide to Vacuum Horizontal Mixers

2025-12-13 10:03

2. Why Oxidation Ruins Jam Quality & How Vacuum Mixing Solves It When fruit pulp is exposed to air during mixing, enzymatic browning occurs, dulling the natural reds of strawberries and purples of blueberries. Vacuum horizontal mixers remove air from the mixing chamber, creating an oxygen-free environment that: * Preserves carotenoids and anthocyanins (natural pigments) * Locks in vitamin C and heat-sensitive nutrients * Prevents flavor degradation caused by airborne contaminants

2. Why Oxidation Ruins Jam Quality & How Vacuum Mixing Solves It When fruit pulp is exposed to air during mixing, enzymatic browning occurs, dulling the natural reds of strawberries and purples of blueberries. Vacuum horizontal mixers remove air from the mixing chamber, creating an oxygen-free environment that: * Preserves carotenoids and anthocyanins (natural pigments) * Locks in vitamin C and heat-sensitive nutrients * Prevents flavor degradation caused by airborne contaminants  3. 360° Mixing: The Key to Uniform Texture Without Damage Unlike vertical agitators that leave dead zones, horizontal mixers with bidirectional blades ensure every particle—whether chunk, granule, or paste—is uniformly blended. Our design features: * Alternating forward/reverse rotation for 360° material movement * Gentle handling that maintains fruit integrity * No cross-contamination between batches

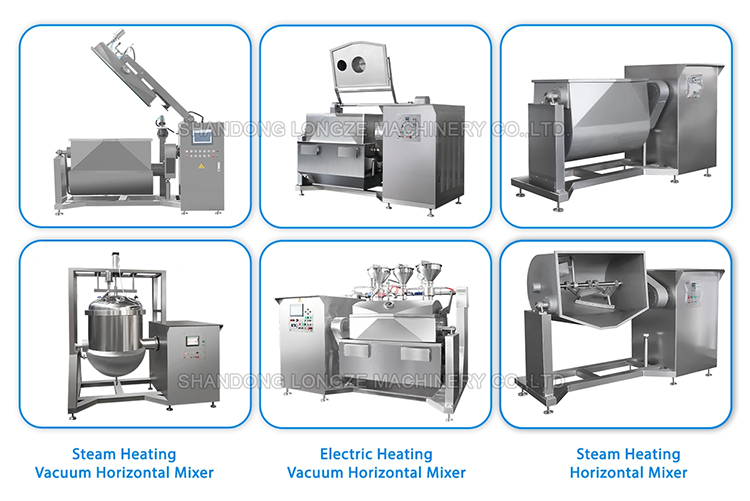

3. 360° Mixing: The Key to Uniform Texture Without Damage Unlike vertical agitators that leave dead zones, horizontal mixers with bidirectional blades ensure every particle—whether chunk, granule, or paste—is uniformly blended. Our design features: * Alternating forward/reverse rotation for 360° material movement * Gentle handling that maintains fruit integrity * No cross-contamination between batches  4. Heating Options: Steam & Induction for Different Jam Types * Steam Heating Mixers Ideal for high-viscosity jams (e.g., pineapple with fibers). Provides gradual, even heat distribution through jacket heating, preventing caramelization on surfaces. * Induction Heating Mixers Perfect for temperature-sensitive fruits like blueberries. Offers precise digital control (±1°C), rapid heating, and 30% higher energy efficiency than traditional methods. * Capacity Planning: Choosing Between 300L, 500L, and 800L Models 300L: Perfect for R&D, small-batch artisan production 500L: Most popular for mid-scale factories (1-2 ton/day output) 800L: Designed for continuous industrial lines with automated feeding systems

4. Heating Options: Steam & Induction for Different Jam Types * Steam Heating Mixers Ideal for high-viscosity jams (e.g., pineapple with fibers). Provides gradual, even heat distribution through jacket heating, preventing caramelization on surfaces. * Induction Heating Mixers Perfect for temperature-sensitive fruits like blueberries. Offers precise digital control (±1°C), rapid heating, and 30% higher energy efficiency than traditional methods. * Capacity Planning: Choosing Between 300L, 500L, and 800L Models 300L: Perfect for R&D, small-batch artisan production 500L: Most popular for mid-scale factories (1-2 ton/day output) 800L: Designed for continuous industrial lines with automated feeding systems

Quick Navigation

Company Profile

Shandong Longze Machinery Co., Ltd. is a scientific research, production, sales service in one of the enterprises. Located in the famous dinosaur town - Zhucheng, the company over the years committed to the development trend of the food industry, the traditional hand-workshop processing reform for the automation, standardization of production. Through automation design and manufacturing for enterprises to save manpower, improve production rate, reduce production costs. Service customers include baking fillings fried industry, meat products cooked food processing industry, condiment industry, candy industry, vegetable corn processing industry, hotel supplies and fast food and other food processing industry, providing heating and cooking frying, vacuum concentration, sterilization Disinfection and other series of equipment.

TO CHEATE EXCELLENT BOUTIQUE

English

English Español

Español Português

Português Français

Français Italiano

Italiano Deutsch

Deutsch Русский

Русский العربية

العربية हिन्दी

हिन्दी Indonesia

Indonesia ไทย

ไทย Ελληνικά

Ελληνικά Nederlands

Nederlands Türkçe

Türkçe 中文 (简体)

中文 (简体) 日本語

日本語 한국어

한국어