Quick Navigation

- + Ball Shape Popcorn Machine

- + Cooking mixer

- + Horizontal Cooking Mixer Machine

- + Pressure Cooking Pot

- + Coated Peanuts Machine

- + Jacketed Kettle

- + cooking robot machine

- + Vacuum Cooking Pot

- + Blanching Pot Machine

- Electric Induction Popcorn Machine

- Full Automatic Cooking Mixer

- Electric Induction Cooking Mixer

Company Profile

Shandong Longze Machinery Co., Ltd. is a scientific research, production, sales service in one of the enterprises. Located in the famous dinosaur town - Zhucheng, the company over the years committed to the development trend of the food industry, the traditional hand-workshop processing reform for the automation, standardization of production. Through automation design and manufacturing for enterprises to save manpower, improve production rate, reduce production costs. Service customers include baking fillings fried industry, meat products cooked food processing industry, condiment industry, candy industry, vegetable corn processing industry, hotel supplies and fast food and other food processing industry, providing heating and cooking frying, vacuum concentration, sterilization Disinfection and other series of equipment.

Large stuffing Cooking Pan for Filling Processing Factory

2025-11-20 15:31Contact Number:+86 13070769155

In terms of fillings preparation, our cooking pan is undoubtedly the king of equipment. The preparation of fillings for traditional Chinese pastries such as moon cakes, glutinous rice balls, and steamed buns all rely heavily on the wok. Take red bean paste as an example: traditional methods are time-consuming and labor-intensive, and it's difficult to guarantee consistent quality from batch to batch. Our large-scale filling cooking pan, however, can precisely control the cooking temperature and time. Through a unique stirring system, it ensures that the red beans are heated evenly in the wok, fully releasing their natural sweetness, resulting in a delicate and smooth red bean paste. Besides red bean paste, it can easily handle the preparation of various fillings such as lotus seed paste, jujube paste, and meat fillings, providing food companies with a stable and efficient filling production solution.

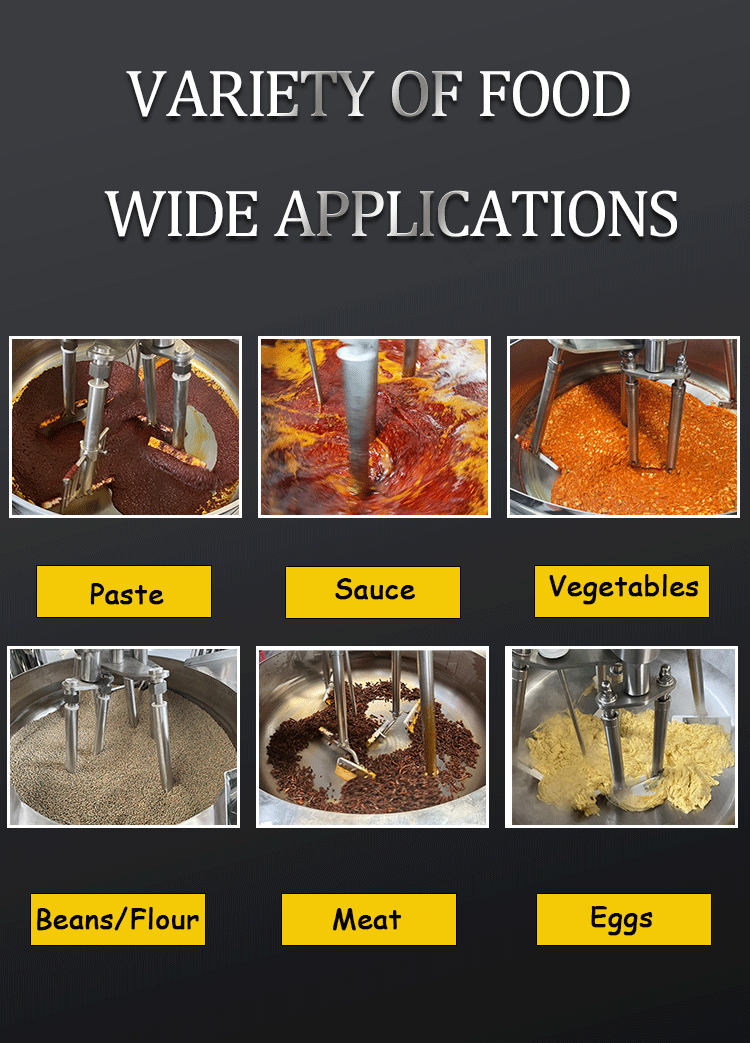

Wide Applications of the Cooking Mixer Machine

It also excels in the sauce production field. Whether it's common table tomato sauce, fermented bean paste, or uniquely flavored salad dressings, caramel, and barbecue sauce, this stir-fryer handles them all perfectly. When stir-frying tomato sauce, it quickly heats the tomatoes to the appropriate temperature, fully preserving their natural color and nutrients. Simultaneously, high-speed stirring ensures a smooth and even texture with a rich and mellow flavor. For sauces requiring special processes, such as hot pot broth that needs long simmering, the stir-fryer's precise temperature control ensures that various spices fully blend at different stages, releasing unique aromas and flavors to satisfy consumers' ultimate pursuit of "fresh, fragrant, spicy, and numbing" hot pot broth.

This stir-fry cooking machine also plays a crucial role in meat processing. When making meat floss, after cooking the meat, it's placed in the stir-fryer. Through continuous stirring and moderate heating, the meat chunks are quickly broken up and dried, forming fluffy and delicious meat floss. Moreover, during the stir-frying process, various seasonings can be added according to different taste preferences, making the meat floss taste richer and more diverse.

Advantages of Fillings Cooking Pot

1. Diverse Heating Methods

This large-scale filling fryer is equipped with multiple advanced heating methods to meet the needs of different users and production scenarios. Among them, steam heating, with its high efficiency and environmental friendliness, has become the preferred choice for many food companies. Steam, as a heat source, can quickly and evenly transfer heat to the pot, allowing materials to reach the appropriate frying temperature in a short time. Its thermal efficiency is extremely high, which can greatly shorten the production cycle and improve production efficiency. At the same time, the steam heating process is relatively clean, producing fewer pollutants, which aligns with the current concepts of green production and sustainable development, reducing the environmental pressure on food companies.

2. Planetary Stirring for Thorough Stirring and No Sticking

The stirring device is one of the core components of this filling fryer, employing a unique planetary stirring method. The planetary stirrer combines revolution and rotation, with a non-integer transmission ratio. This design ensures that there are no dead zones in the pot, allowing materials to be fully and evenly stirred. When frying fillings, whether it's delicate red bean paste or meat filling containing granular materials, the planetary stirrer can perfectly blend various ingredients, ensuring a consistent taste in every bite.

3. Durable and Easy-to-Clean Stainless Steel Pot Body

As a key component of the wok, the pot body is made of high-quality 304 stainless steel. This material boasts advantages such as acid resistance, heat resistance, and corrosion resistance, ensuring that the pot body will not deform or rust during prolonged high-temperature frying, guaranteeing the lifespan of the equipment and the hygiene and safety of food. The pot body features a one-piece molded hemispherical structure, which not only provides high strength but also facilitates stirring and frying of materials, reducing material residue in the pot and improving production efficiency and product quality.

Furthermore, the pot body incorporates a tilting design, greatly facilitating material discharge and cleaning. After frying, the pot body can be easily tilted via a hydraulic system to quickly and thoroughly empty the material, eliminating the need for manual shoveling, reducing labor intensity, and improving work efficiency. Moreover, the tilting design fully exposes the interior of the pot, allowing for comprehensive and thorough cleaning by staff, ensuring cleanliness and hygiene, avoiding the risk of material residue and cross-contamination, and providing excellent conditions for the next production run.

From a production efficiency perspective, the large capacity design of this large-scale filling cooking pan allows it to process large quantities of material at once, significantly increasing batch output. The increased automation also effectively reduces labor costs. Traditional manual cooking or cooking with small equipment requires a large amount of manual labor, is labor-intensive, and prone to human error. Our large-capacity fillings cooking pan, equipped with an advanced automated control system, requires only a few operators to complete the entire cooking process, reducing manpower and improving production stability and accuracy.

We also provide customers with regular equipment follow-up visits and maintenance services to ensure the equipment is always in optimal operating condition and extends its lifespan. Furthermore, we offer operation training and technical consulting services to help our customers' operators master the equipment's operation skills and maintenance knowledge, improving production efficiency and product quality.

TO CHEATE EXCELLENT BOUTIQUE

English

English Español

Español Português

Português Français

Français Italiano

Italiano Deutsch

Deutsch Русский

Русский العربية

العربية हिन्दी

हिन्दी Indonesia

Indonesia ไทย

ไทย Ελληνικά

Ελληνικά Nederlands

Nederlands Türkçe

Türkçe 中文 (简体)

中文 (简体) 日本語

日本語 한국어

한국어