Quick Navigation

- + Ball Shape Popcorn Machine

- + Cooking mixer

- + Horizontal Cooking Mixer Machine

- + Pressure Cooking Pot

- + Coated Peanuts Machine

- + Jacketed Kettle

- + cooking robot machine

- + Vacuum Cooking Pot

- + Blanching Pot Machine

- Electric Induction Popcorn Machine

- Full Automatic Cooking Mixer

- Electric Induction Cooking Mixer

Company Profile

Shandong Longze Machinery Co., Ltd. is a scientific research, production, sales service in one of the enterprises. Located in the famous dinosaur town - Zhucheng, the company over the years committed to the development trend of the food industry, the traditional hand-workshop processing reform for the automation, standardization of production. Through automation design and manufacturing for enterprises to save manpower, improve production rate, reduce production costs. Service customers include baking fillings fried industry, meat products cooked food processing industry, condiment industry, candy industry, vegetable corn processing industry, hotel supplies and fast food and other food processing industry, providing heating and cooking frying, vacuum concentration, sterilization Disinfection and other series of equipment.

14 Years Manufacturer of Sauce Industrial Cooking Pan

2025-11-22 16:10In the sauce production industry, a high-efficiency and stable industrial cooking pan is a core piece of equipment for ensuring

Contact Number:+86 13070769155As a manufacturer with 14 years of professional experience in producing industrial pans for sauces, we are always market-oriented, creating high-quality pan equipment suitable for various sauce production scenarios. Below, we will comprehensively introduce our industrial cooking pan products from three aspects: applications, features, and key advantages.

I.Diverse Application Scenarios, Covering the Entire Sauce Production Sector

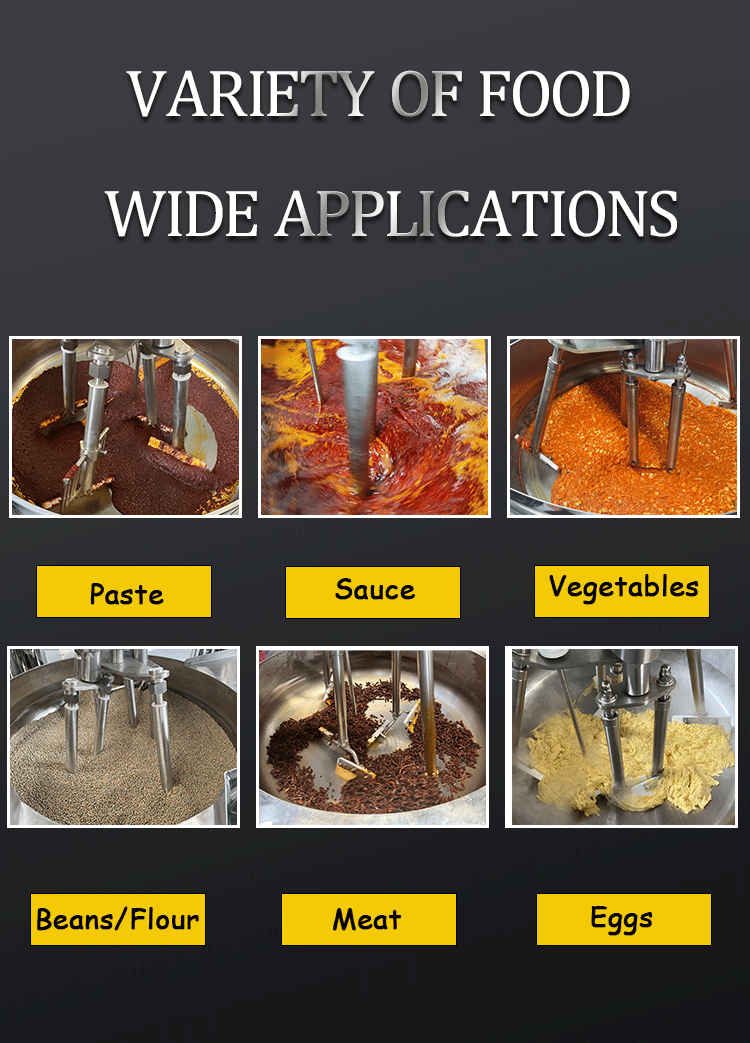

After 14 years of market refinement and technological iteration, our industrial cooking mixer machine have formed a complete product system, capable of precisely matching the processing needs of different sauce categories and production scales. They are widely used in various sauce production scenarios within the food processing industry:

1. Traditional Flavor Sauces: Covering fermented or stir-fried traditional sauces such as broad bean paste, chili sauce, and garlic sauce, meeting the requirements of long-term low-temperature slow stir-frying and post-fermentation maturation processes, restoring the authentic flavor of the sauce.

2. Compound Seasoning Sauces: Suitable for the production of compound sauces such as hot pot base, spicy hot pot base, barbecue sauce, noodle sauce, and rice sauce. Supporting precise proportions of various ingredients (oils, spices, food particles, etc.) for stir-frying, ensuring uniform and stable sauce flavor.

3. Specialty Functional Sauces: Including targeted categories such as salad dressing, ketchup, jam, seafood sauce, and beef sauce. Stir-frying parameters can be customized according to the sauce's viscosity, moisture content, heat sensitivity, and other characteristics to ensure product taste and nutrition.

4. Large-scale food processing support: Provides batch production solutions for central kitchens of catering chain enterprises, food processing plants, sauce production bases, etc., which can meet the production capacity requirements from tens of kilograms to several tons, and are compatible with automated production lines.

II. Core Technological Features Showcasing Professional Manufacturing Strength

14 years of focused effort and accumulation have given us unique advantages in the structural design, process optimization, and performance upgrades of industrial cooking kettle.

Our products possess the following core features:

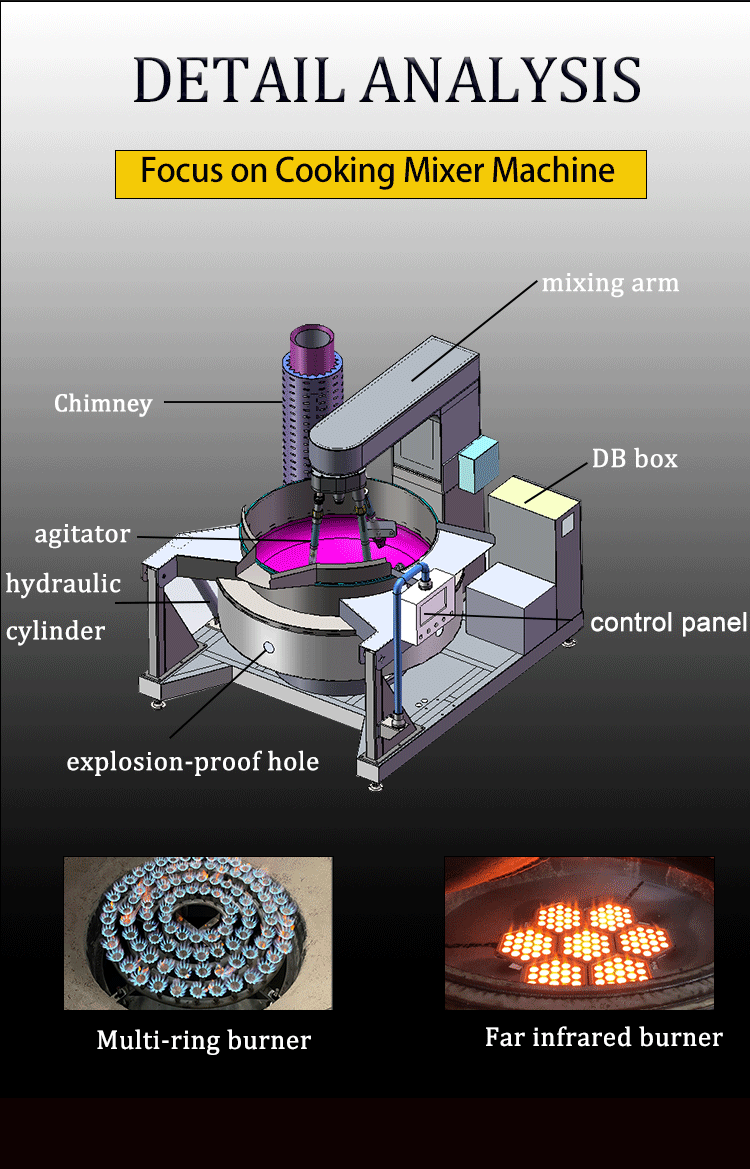

1. Customized Heating Methods, Adaptable to Diverse Processes: Supports multiple heating modes including steam heating, electric heating, gas heating, and electromagnetic heating.

The appropriate mode can be flexibly selected based on the required cooking temperature and production site conditions. The heating system employs a uniform distribution design to ensure consistent heating of the bottom and walls of the wok, preventing localized scorching or uneven cooking.

2. Scientific Stirring Structure, Balancing Efficiency and Quality: The stirring paddle conforms to the curvature of the pot body and features variable frequency speed control (adjustable from 0-60 rpm), enabling both gentle stirring and vigorous stir-frying. For high-viscosity sauces, the stirring force and angle are specially optimized to ensure thorough mixing of ingredients while minimizing breakage and preserving a grainy texture, while also preventing sauce from sticking to the sides and wasting.

3. Premium Material Selection, Upholding Safety Standards: The pot body is made of 304 or 316L stainless steel, meeting food-grade safety standards.

It is corrosion-resistant, high-temperature resistant, easy to clean, and eliminates the risk of heavy metal leaching.

4. Intelligent Control System, Simplified Operation: Equipped with a touchscreen human-machine interface, it allows for precise setting of parameters such as heating temperature, stirring speed, and cooking time. Parameter storage and retrieval are supported, reducing human error. A PLC control system is also available as an option, automating processes such as feeding, cooking, discharging, and cleaning, reducing labor costs and improving production standardization.

5. User-Friendly Design, Enhanced Experience: The pot body features a tiltable design with an adjustable discharge angle (0-90°C), ensuring thorough and residue-free discharge. The equipment is equipped with safety protection devices (overload protection, leakage protection, high-temperature warning, etc.) to ensure operator safety. The modular design facilitates easy installation, disassembly, and maintenance, saving space.

III. Core Product Advantages

1. Stable and Reliable Quality, Long Service Life: Each wok undergoes rigorous raw material inspection, precision machining, and finished product testing, ensuring a core component lifespan of 8-10 years.

2. High Cooking Efficiency, Flexible Production Capacity: Optimized heating structure and stirring system significantly improve thermal efficiency (over 75%). Compared to traditional woks, cooking time is reduced by 20%-30%. Production capacity can be flexibly customized from 50kg/batch to 500kg/batch, meeting the full lifecycle needs from small-batch trial production to large-scale mass production.

3. Outstanding Sauce Quality, Strong Flavor Consistency: Precise temperature control and uniform stirring ensure even heating and full flavor absorption, effectively preventing burning and clumping.

This guarantees high consistency in flavor, color, and taste for each batch of sauce, helping customers build core product competitiveness.

4. Customized services to meet specific needs: Leveraging 14 years of industry experience, we can provide one-on-one customized solutions. Based on the individual needs of sauce types, production processes, and site conditions, we adjust equipment parameters, structural design, and functional configurations to ensure a perfect fit between the equipment and the customer's production process.

With 14 years of dedicated focus on manufacturing industrial sauce cooking pan, we have witnessed the growth and development of countless sauce companies. In the future, we will continue to iterate and upgrade our product technology and services, providing more sauce manufacturers with higher-quality, more efficient, and more intelligent industrial cooking equipment! If you have purchasing needs for industrial sauce woks or customization inquiries, please feel free to contact us. We will provide you with professional solutions and attentive service.

TO CHEATE EXCELLENT BOUTIQUE

English

English Español

Español Português

Português Français

Français Italiano

Italiano Deutsch

Deutsch Русский

Русский العربية

العربية हिन्दी

हिन्दी Indonesia

Indonesia ไทย

ไทย Ελληνικά

Ελληνικά Nederlands

Nederlands Türkçe

Türkçe 中文 (简体)

中文 (简体) 日本語

日本語 한국어

한국어