Quick Navigation

- + Ball Shape Popcorn Machine

- + Cooking mixer

- + Horizontal Cooking Mixer Machine

- + Pressure Cooking Pot

- + Coated Peanuts Machine

- + Jacketed Kettle

- + cooking robot machine

- + Vacuum Cooking Pot

- + Blanching Pot Machine

- Electric Induction Popcorn Machine

- Full Automatic Cooking Mixer

- Electric Induction Cooking Mixer

Company Profile

Shandong Longze Machinery Co., Ltd. is a scientific research, production, sales service in one of the enterprises. Located in the famous dinosaur town - Zhucheng, the company over the years committed to the development trend of the food industry, the traditional hand-workshop processing reform for the automation, standardization of production. Through automation design and manufacturing for enterprises to save manpower, improve production rate, reduce production costs. Service customers include baking fillings fried industry, meat products cooked food processing industry, condiment industry, candy industry, vegetable corn processing industry, hotel supplies and fast food and other food processing industry, providing heating and cooking frying, vacuum concentration, sterilization Disinfection and other series of equipment.

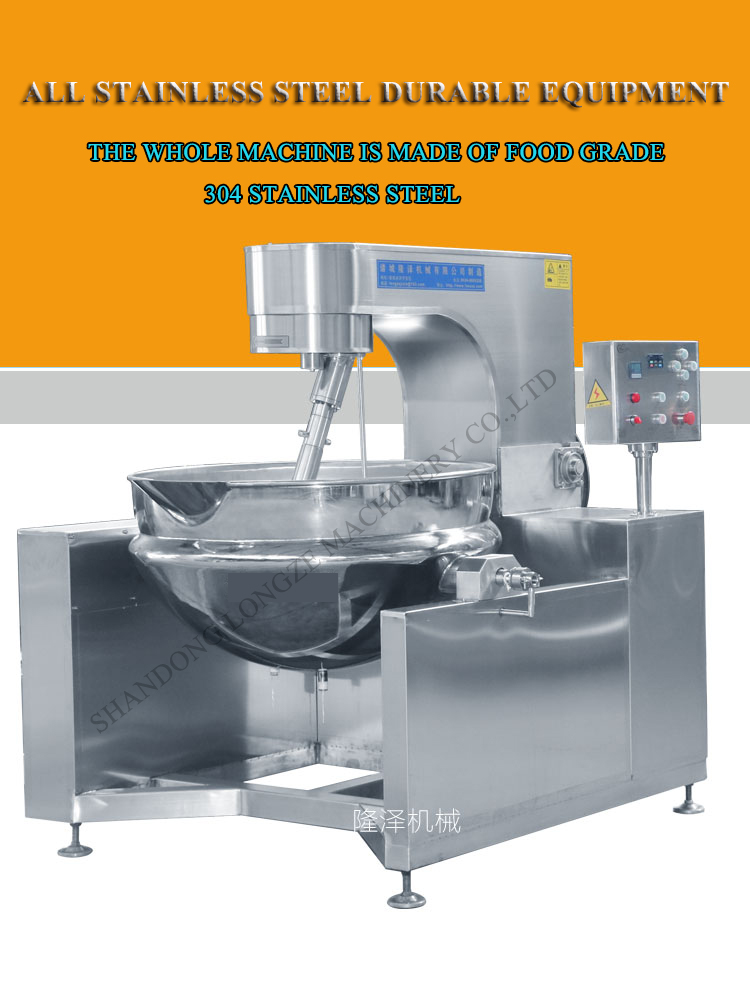

Fillings Cooking Mixer Machine

2021-07-04 15:23Contact Number:+86 13070769155

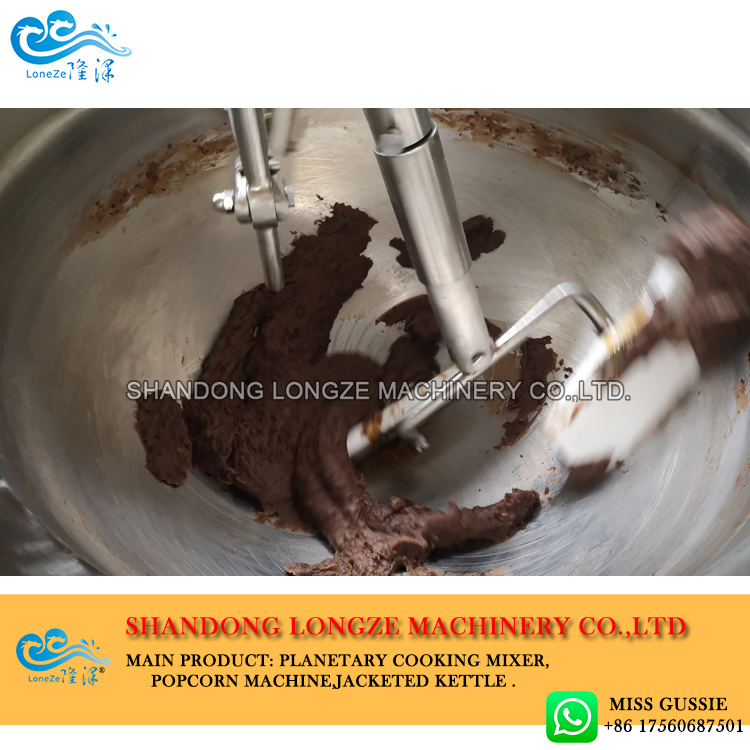

Bean Paste Fillings Cooking Mixer

Longze bean paste fillings cooking mixer is mainly composed of a pot body, a frame body, a stirring system, a heating system, a speed-regulating transmission device, a stirring shaft, and a pot body turning system. The planetary cooking mixer is divided into manual and automatic in type. From the heating form, it is divided into: steam type, gas type, gas thermal oil and electric thermal oil.

(Note: The sales volume of gas thermal oil is less than other products)

The mixing system of Longze fillings cooking mixer adopts a combination of rotation and revolution, and its transmission ratio is an integer transmission ratio to ensure that there are no blind spots in the pan. Use advanced transmission and sealing structure to make the transmission part and the pot clean and hygienic. The automatic/hydraulic type of this series of equipment uses hydraulic thrust to turn the stirring arm over, without disassembly and assembly of the stirrer, and then uses the hydraulic thrust to tilt the pot body, which is easy to enter and exit the raw materials and save manpower. The stepless frequency converter can mix high viscosity products. Uniform heating increases heat. It has the characteristics of easy operation, high work efficiency, low energy consumption, long service life, compact structure and convenient maintenance. It is a mixer with excellent performance.

Automatic Model

| Capacity(L) | Diameter(mm) | Power(KW) | Speed(min) | Stirring Type | Discharger Type | Heating Source | |

| rotation | revolution | ||||||

| 200L | φ900 | 3.7 | 6.7-33 | 14-69.3 | Planetary | Automatic hydraulic | Gas/Steam/Thermal oil |

| 300L | φ1000 | 3.7 | 6.7-33 | 14-69.3 | Planetary | Automatic hydraulic | Gas/Steam/Thermal oil |

| 400L | φ1100 | 3.7 | 6.7-33 | 14-69.3 | Planetary | Automatic hydraulic | Gas/Steam/Thermal oil |

Manual Model

| Capacity(L) | Diameter(mm) | Power(KW) | Speed(min) | Stirring Type | Discharger Type | Heating Source | |

| rotation | revolution | ||||||

| 200L | φ900 | 3.7 | 6.7-33 | 14-69.3 | Planetary | Manual | Gas/Steam/Thermal oil |

| 300L | φ1000 | 3.7 | 6.7-33 | 14-69.3 | Planetary | Manual | Gas/Steam/Thermal oil |

| 400L | φ1100 | 3.7 | 6.7-33 | 14-69.3 | Planetary | Manual |

Gas/Steam/Thermal oil |

Note:

TO CHEATE EXCELLENT BOUTIQUE

English

English Español

Español Português

Português Français

Français Italiano

Italiano Deutsch

Deutsch Русский

Русский العربية

العربية हिन्दी

हिन्दी Indonesia

Indonesia ไทย

ไทย Ελληνικά

Ελληνικά Nederlands

Nederlands Türkçe

Türkçe 中文 (简体)

中文 (简体) 日本語

日本語 한국어

한국어