Quick Navigation

- + Ball Shape Popcorn Machine

- + Cooking mixer

- + Horizontal Cooking Mixer Machine

- + Pressure Cooking Pot

- + Coated Peanuts Machine

- + Jacketed Kettle

- + cooking robot machine

- + Vacuum Cooking Pot

- + Blanching Pot Machine

- Electric Induction Popcorn Machine

- Full Automatic Cooking Mixer

- Electric Induction Cooking Mixer

Company Profile

Shandong Longze Machinery Co., Ltd. is a scientific research, production, sales service in one of the enterprises. Located in the famous dinosaur town - Zhucheng, the company over the years committed to the development trend of the food industry, the traditional hand-workshop processing reform for the automation, standardization of production. Through automation design and manufacturing for enterprises to save manpower, improve production rate, reduce production costs. Service customers include baking fillings fried industry, meat products cooked food processing industry, condiment industry, candy industry, vegetable corn processing industry, hotel supplies and fast food and other food processing industry, providing heating and cooking frying, vacuum concentration, sterilization Disinfection and other series of equipment.

Industrial Electric Heating Jacketed Kettle

2025-11-02 16:18Contact Number:+86 13070769155

Product description

The electric heating jacketed pot uses heat-conducting oil as the medium, is connected to the power supply and heats the heat-conducting oil through the electric heating tube to generate heat. The jacketed kettle has the characteristics of large heating area, high thermal efficiency, uniform heating, short boiling time of liquid material, and easy control of heating temperature. The inner pot body (inner pot) of the jacketed pot is made of acid-resistant and heat-resistant austenitic stainless steel, which is beautiful in appearance, easy to install, convenient to operate, safe and reliable.

Application of electric heating sandwich pot

Electric heating sandwich pot is widely used in the processing of candy, pharmacy, dairy products, alcohol, cakes, preserves, beverages, cans, stews and other foods. It can also be used in large restaurants or canteens for soup, cooking, stew and porridge. It is a good equipment for food processing to improve quality, shorten time and improve working conditions.

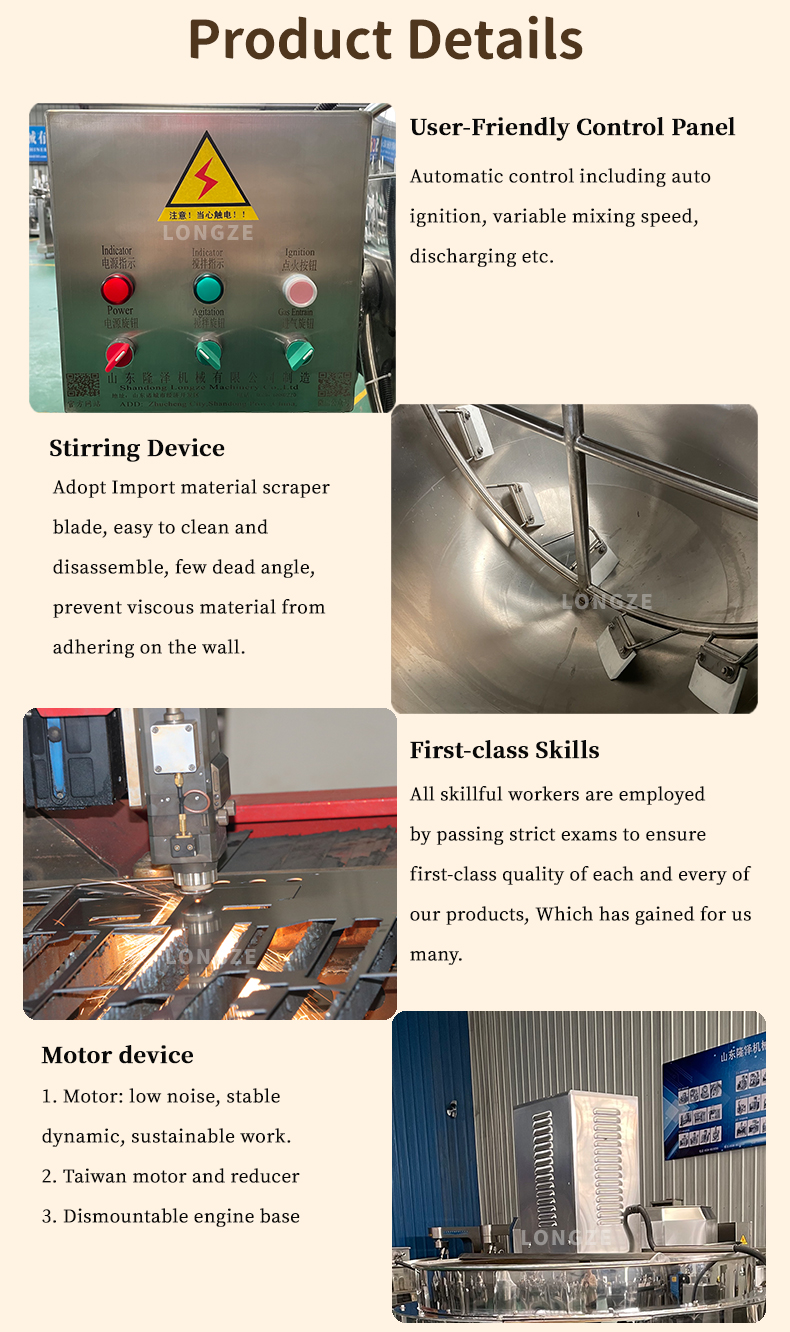

Jacketed kettle product structure

1. According to the structural form, it is divided into tilting jacketed kettle and vertical (fixed) jacketed kettle.

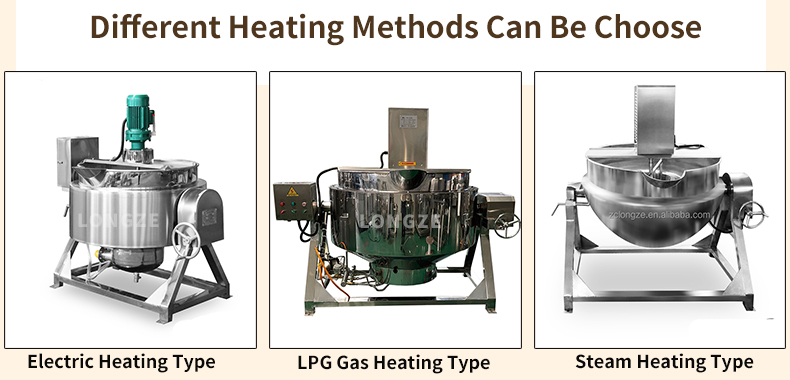

2. According to the heating mode, it is divided into electric heating jacketed kettle, steam heating jacketed kettle, gas heating jacketed kettle and electromagnetic heating jacketed kettle.

3. Mixing equipment with or without mixing equipment shall be adopted according to the process needs.

4. According to the sealing mode, the jacketed kettle can be divided into: uncovered type, flat cover type and vacuum type.

How to use electric heating jacketed pot

1. Before starting the machine, check whether the oil level of the heat transfer oil reaches the specified oil level (150cm under the interlayer).

2. Clean the pot and put in the materials.

3. Before starting the machine, the oil filling valve above should be opened first.

4. Turn on the switch, turn on the red switch, and turn on the electric heating tube for heating, and normal production can be carried out.

5. Turn off the electric switch, close the oil filling valve, the jacketed pot can be tilted, and the handwheel can be turned to tilt the pot body for unloading.

Instructions for using electric heating jacketed pot

1. The power supply must be equipped with a leakage protector according to the power, and heat-conducting oil must be added before use.

2. It is strictly forbidden to start the machine without thermal oil installed in the interlayer.

3. It is recommended to replace the heat transfer oil about once a year. If the working time is not long, the replacement time can be extended.

4. After the work, close the oil valve, then tilt the pot body to pour out the material.

5. It is recommended to use a standard copper core power cord of more than 6mm.

6. In order to keep it clean, the pot should be cleaned every time it is used.

7. Regularly check the meshing degree of the worm gear and the worm. If the gap is too large, it can be adjusted by the bearing on the worm.

8. If the machine cannot work normally, you can check whether the fuse is blown, or whether the AC contactor is damaged, and it is recommended to replace it.

Safety tips for electric heated jacketed kettle

1. Before starting the machine, the oil sealing cap on the top should be opened and the air outlet cap inside the distributor box should be replaced in order to release the oil and gas generated by the high temperature during heating, thereby preventing the danger of high pressure in the interlayer.

2. The machine must be grounded effectively, otherwise it may lead to dangerous accidents.

3. After the work is over, it is strictly forbidden to tilt without closing the oil valve, especially tilting outwards, which may cause the high temperature heat transfer oil to overflow and cause an accident.

4. It is strictly forbidden to enter water from the air outlet valve!

TO CHEATE EXCELLENT BOUTIQUE

English

English Español

Español Português

Português Français

Français Italiano

Italiano Deutsch

Deutsch Русский

Русский العربية

العربية हिन्दी

हिन्दी Indonesia

Indonesia ไทย

ไทย Ελληνικά

Ελληνικά Nederlands

Nederlands Türkçe

Türkçe 中文 (简体)

中文 (简体) 日本語

日本語 한국어

한국어